Hebei Messi Biology Co., Ltd. stated that the electric heating tube is composed of electric heating wire (heating wire), metal skin and insulating magnesium oxide powder. The material of each link is very important, but if the quality of the magnesium oxide powder is unqualified or the installation If it is not in place, it will directly affect the service life of the electric heating tube. How to correctly install magnesium oxide powder in electric heating tubes can better lead to the excellent quality of electric heating tubes. The role of magnesium oxide powder in electric heating tubes:

① Magnesium oxide powder is located between the heating wire and the pipe wall and is used for insulation between the heating wire and the pipe wall. At the same time, magnesium oxide powder has good thermal conductivity. However, magnesium oxide powder has strong hygroscopicity, so it must undergo moisture-proof treatment (magnesium oxide powder modification or electric heating tube sealing treatment) when used.

② Magnesium oxide powder can be divided into two types: low-temperature powder and high-temperature powder according to the temperature range of use. Low-temperature powder can only be used below 400°C, and is generally modified magnesium oxide powder.

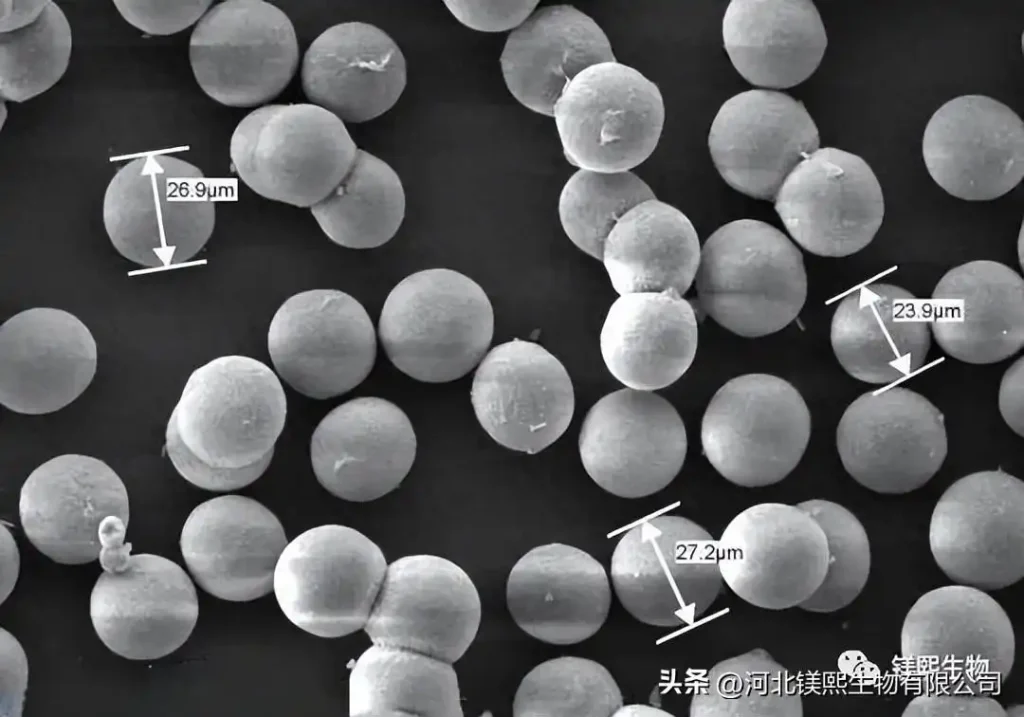

③ Magnesium oxide powder is in granular form. The magnesium oxide powder used for electric heating tubes is composed of magnesium oxide powder particles of different thicknesses according to a certain ratio (mesh ratio).