Die MagChem®-Produktlinie von Tibet Mag bietet eine Vielzahl von Chemikalien und physikalischen Eigenschaften für eine Vielzahl von industriellen Anwendungen weltweit. Die hohe Reinheit und Konsistenz der MagChem-Produkte bietet überlegene Leistung in einem breiten Anwendungsbereich, wie zum Beispiel:

Industrielle Anwendung zum Gerben von Leder

Bei der Ledergerbung sorgt MagChem für eine gleichmäßige und kontrollierte pH-Erhöhung, sodass das Chrom gleichmäßig in die Lederhäute eindringen und vollständig mit dem Kollagen reagieren kann, wodurch Fleckenbildung vermieden wird. Eine einmalige Zugabe von MagChem zu Beginn des Chrom-Basenschritts erfordert weniger Arbeit als Natrium- oder Kalzium-basierte Basen. Darüber hinaus enthält neutralisiertes Chrom wasserlösliches Magnesiumsulfat, das für Leder unschädlich ist.

Bohrflüssigkeiten und Zemente – Industrielle Anwendung

MagChem 10 oder MagChem P98 Pulverized können Portlandzement zugesetzt werden, um eine dichtere Abdichtung für Bohrlöcher zu erreichen. Nachdem Portlandzement ausgehärtet ist, hydratisiert und dehnt sich MagChem-Magnesiumoxid aus, wodurch eine feste Verbindung zwischen Boden und Rohreinsatz entsteht. MagChem-Magnesiumoxidprodukte mit leichtem Brand können als Viskositätsmodifikator in Bohrschlämmen verwendet werden.

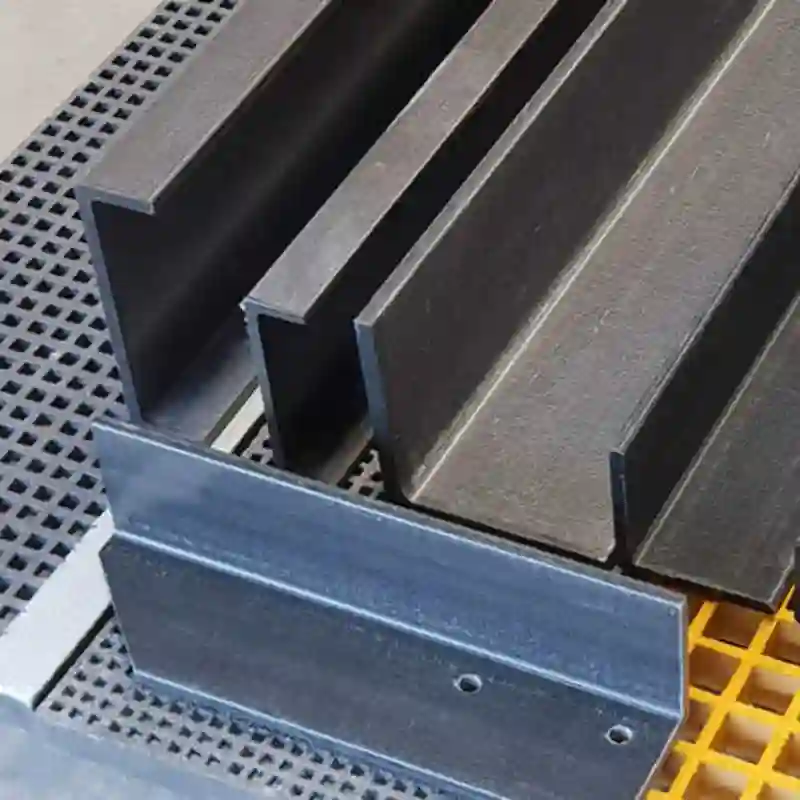

Magnesiumoxid für FRP, GRP und SMC – industrielle Anwendung

FRP wird auch Verbundwerkstoff genannt und seine chemische Verdickung ist ein wichtiger Schritt im Herstellungsprozess von Sheet-Molding-Compounds. Wenn die Verdickung zu schnell erfolgt, ist es für die Glasfaser schwierig, einzudringen, die Fließfähigkeit des Materials ist schlecht und es kann leicht zu Materialmangel oder Abrieb während des Formens kommen. Wenn die Verdickung zu langsam erfolgt, geht das Harz während des Formens leicht verloren, was zu instabilen mechanischen Eigenschaften führt. Daher ist es sehr wichtig, ein spezielles Verdickungsmittel für FRP zu entwickeln.

Derzeit bestehen die Verdickungsmittel hauptsächlich aus Magnesiumoxid oder Magnesiumhydroxid und Isocyanat. Isocyanat ist jedoch eine hochgiftige Substanz und daher nicht für den Umweltschutz geeignet. Calciumoxid reagiert empfindlich auf Luftfeuchtigkeit und wird daher im Allgemeinen nicht verwendet. Magnesiumoxid ist derzeit das am häufigsten verwendete chemische Verdickungsmittel und bietet viele Vorteile, z. B. eine schnelle Verdickungsgeschwindigkeit und eine breite Rohstoffquelle.

Die Rolle von Magnesiumoxid in Verbundwerkstoffen ist sehr wichtig. Es kann als Verdickungsmittel wirken und die Helligkeit von FRP erhöhen. Daher wird FRP, das normalerweise mit Magnesiumoxid hergestellt wird, im Vergleich zu FRP desselben Typs auf dem Markt beliebter sein. Allerdings können nicht alle Arten von Magnesiumoxid zu FRP hinzugefügt werden. Im Allgemeinen empfehlen wir die Verwendung von reaktivem Magnesiumoxid als Verdickungsmittel und zur Erhöhung der Helligkeit mit einem Gehalt von ≥90 %, guter Weiße und guter Dispersion. Solches Magnesiumoxid ist nützlicher.

Weitere industrielle Anwendungsgebiete für MagChem-Produkte sind:

- Schleifmittel

- Bauprodukte

- Chemikalien

- Zahnärztliche Investitionen

- Kraftstoffzusätze

- Magnesiumsalze

- Bergbau

- Feuerfest und Stahlherstellung

- Straßenflickzement

- Kieselsäureentfernung

- Zuckerraffination

- Glasfaserverstärkte Kunststoffe FRP, GFK, SMC