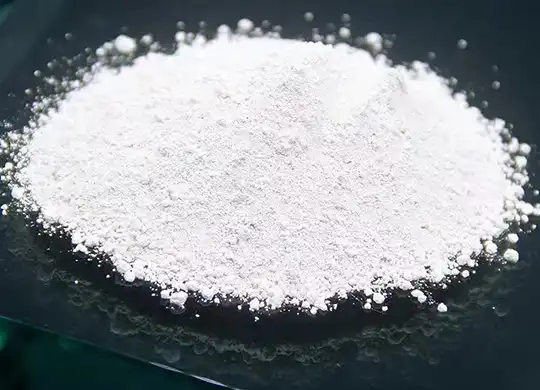

Hebei Messi Biology Co., Ltd. stated that a preparation method of silicon steel grade magnesium oxide coating specially used for oriented silicon steel sheet includes the following process steps: select natural cryptocrystalline magnesite to produce light-burned magnesium oxide powder; digest the light-burned magnesium oxide, neutralize and decalcify with acid and alkali, react at a temperature of 15-30℃ and a time of 5-15 minutes to generate magnesium hydroxide, and then wash, filter, and dry it, and then calcine it at a temperature of 1100±50℃ and a time of 2.0±0.5 hours to obtain high-purity magnesium oxide; use air flow grinding to process it into the required micron-level particle size segment.

In order to improve the reactivity between magnesium oxide and silicon dioxide, magnesium oxide must be active, and nano-magnesium oxide has the greatest reactivity. Therefore, nano-magnesium oxide particles are introduced into magnesium oxide for silicon steel coating using nanotechnology to improve the reactivity of silicon steel magnesium oxide. In order to improve the packing density between magnesium oxide particles on the surface of silicon steel sheets, the structure of magnesium oxide particles for silicon steel coating must tend to be approximately spherical, because spheres have the advantage of the most compact packing, and magnesium oxide particles can be most compactly packed after being coated on the surface of silicon steel sheets.

After magnesium oxide acts on silicon steel sheets, it must be dried and curled into a coil for secondary high-temperature annealing. Before entering the high-temperature annealing stage, the water molecules in the magnesium hydroxide generated by magnesium oxide during the pulping process must be gradually driven away during the annealing and heating process. In the implementation of this process, the coated magnesium oxide layer must have good air permeability, even if the water molecules in magnesium oxide can escape in the gaps of the tightly rolled steel coils, so as to prevent water vapor from affecting the quality of the generated orthosilicate magnesium film. Therefore, as magnesium oxide for high-temperature annealing, a single nano magnesium oxide material cannot be used, but the magnesium oxide should be a collection of magnesium oxides with various particle sizes, that is, magnesium oxide materials with various particle sizes should each occupy a certain distribution ratio.

The magnesium oxide for silicon steel coating produced by Hebei Messi Biology Co., Ltd. has the characteristics of high chemical purity, low impurity ions, good suspension, low hydration rate, good coating and adhesion. Its physical properties are far superior to similar products, and it is a good annealing isolation agent for the production of oriented silicon steel sheets. Moreover, the production process is simple and the production cost is greatly reduced.