Spherical alumina and spherical magnesium oxide are both developed with the continuous development of technology in the electronics industry. At present, spherical alumina is still the main force of commercial thermal conductive fillers, but the thermal conductivity of spherical magnesium oxide can be up to 1.5 times that of spherical alumina. It greatly enhances customers’ flexibility in thermal management, so it is also called the “next generation thermal filler” connected to ball-shaped alumina.

In the past few years, the domestic thermal conductive material industry has been using imported magnesium oxide products. However, due to after-sales and other problems, foreign companies have often not been able to effectively solve quality problems when thermal conductive material manufacturers have problems. Hebei Messi Biology Co., Ltd. In order to change this situation, we developed magnesium oxide for domestic thermal conductive materials that surpasses imported brands.

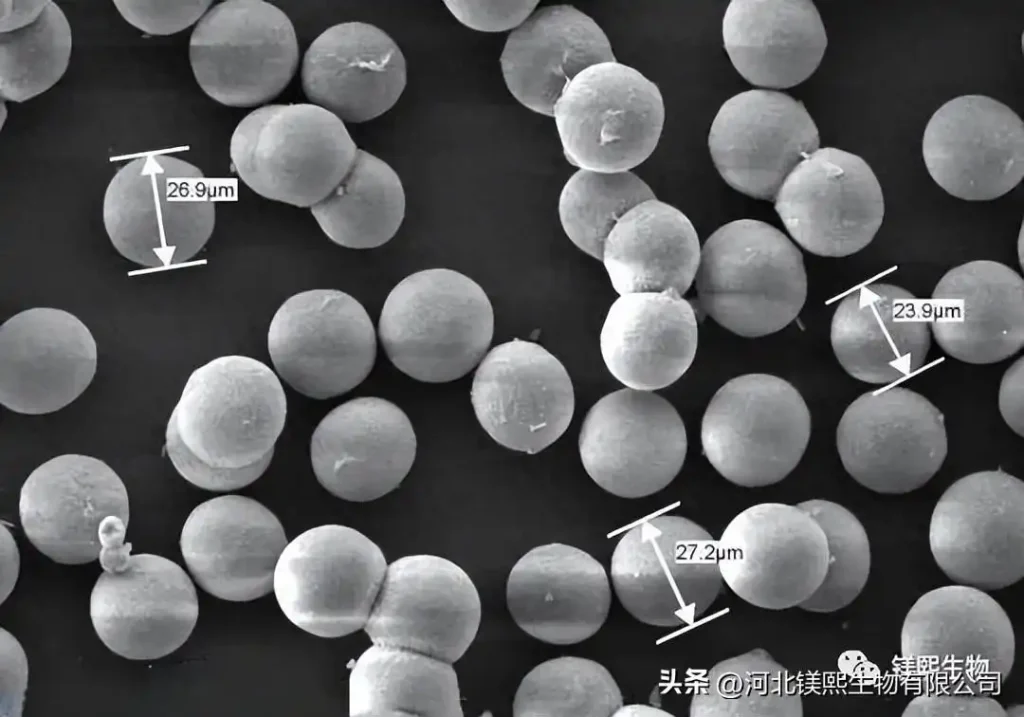

Magnesium oxide for thermal conductivity independently developed by Hebei Messi Biology Co., Ltd. has a magnesium oxide content of ≥98.0%, an average particle size (D50) of 50~60μm, a specific surface area of 0.2m2/g, a specific gravity of 3.6g/cm3, and a single crystal thermal conductivity of 40~ 60W/m.k, Mohs hardness 5.5. Easy to disperse and mix, can be filled at a high proportion; high thermal conductivity, single crystal thermal conductivity is higher than alumina; low hardness, not easy to wear equipment, can be used to produce high whiteness thermally conductive plastics; mainly used in thermally conductive plastics, thermally conductive silicone pads, thermal conductivity Potting glue, thermal conductive cement, etc.