I. Overview

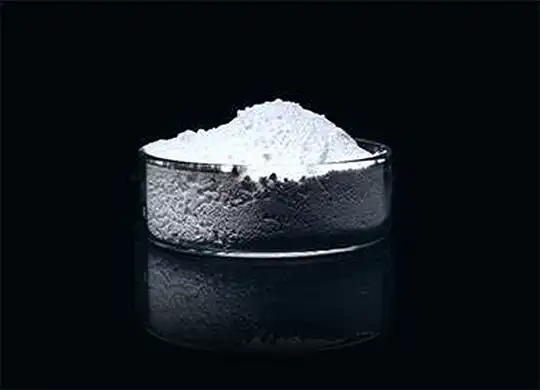

Typically, magnesium oxide exists in the form of flaky crystals, however, some special morphologies have effective applications in many aspects. Especially spherical magnesium oxide, it has shown excellent performance in many fields, such as as a stationary phase material in chromatography, as an adsorption material for toxic substances, and can also be added to plastics to improve their thermal conductivity.

2. Types of thermally conductive fillers

The thermal conductivity of polymer materials is usually low, and the thermal conductivity of most common materials is around 0.3W/m·K. Therefore, in order to improve the thermal conductivity of the polymer, it is necessary to fill it with thermally conductive fillers. By uniformly mixing fillers with high thermal conductivity and polymer matrix, thermally conductive network chains that contact each other can be formed, thereby improving the thermal conductivity of the polymer.

Thermal conductive fillers are mainly divided into three types: carbon-based materials, metallic materials and non-metallic inorganic materials.

Carbon-based materials

The thermal conductivity of some carbon-based materials is significantly higher than that of metallic materials and non-metallic inorganic materials. Due to its unique microstructure, the thermal conductivity of carbon-based materials is anisotropic. Taking graphite as an example, it has a typical layered structure and conducts heat through the dual mechanism of electrons and phonons, so it has good thermal conductivity and low price.

Metal materials

Metal materials are recognized as excellent thermal conductors and are widely used not only in filling polymer materials, but also in aerospace, machinery manufacturing and other fields. There are a large number of free electrons inside metal materials, and the free movement of these free electrons is the main mechanism for thermal conductivity of metal materials. However, due to the high density of metal materials, it is difficult to mix them with polymeric materials, which limits its application as thermally conductive fillers for polymeric materials.

Non-metallic inorganic materials

Non-metallic inorganic materials mainly conduct heat using phonons, and their thermal conductivity is generally lower than carbon-based materials and metal materials. But these materials usually have better insulating properties than other materials. Common non-metallic inorganic fillers include metal nitrides such as BN, AlN and metal oxides such as MgO, Al2O3, etc.

Among oxides, commonly used fillers are aluminum oxide and magnesium oxide. Although aluminum oxide has low thermal conductivity, its cost is not high, so it is widely used in applications. In contrast, although the thermal conductivity of magnesium oxide is lower than that of boron nitride, it is higher than that of aluminum oxide, and its cost is lower, so its application in thermal conductive fillers has attracted increasing attention.

3. The influence of different filler morphologies on thermal conductivity

Adding polymer materials to rod-shaped or sheet-shaped structural fillers with a certain aspect ratio can help form thermally conductive network chains, thereby improving the thermal conductivity of composite materials. However, this type of filler will have orientation distribution during processing, that is, the direction of the rod-like structure is inconsistent, which will lead to anisotropy in the thermal conductivity of the composite material. The thermal conductivity in the processing direction is much higher than that in the perpendicular processing direction. . Therefore, designing and producing fillers with as consistent orientation as possible is key to improving the thermal conductivity efficiency of composites.

In contrast, spherical magnesium oxide fillers have significant advantages in improving the thermal conductivity of composites due to the isotropy of the spherical structure. In addition, the particle size of spherical magnesium oxide powder particles is small and evenly distributed, and the surface morphology is regular, which can significantly improve the fluidity and dispersion of the powder and better eliminate the impact of agglomeration on performance. Therefore, it is a very wise choice to use spherical magnesium oxide fillers during the design and preparation process to enhance the thermal conductivity of composite materials!