Tibet Mag stated that as an important functional inorganic material, magnesium oxide is widely used in metallurgy, electronics, catalysis, ceramics, coatings, medicine, adsorption, refractory materials and optical materials. Mineral direct pyrolysis method, chemical precipitation method, gas phase hydration method, carbonization method, ammonium bicarbonate method, spray pyrolysis method, hydrothermal method, sol-gel method and other methods are used for the preparation of magnesium oxide.

However, there are still many problems restricting the development and application of high value-added magnesium oxide materials, such as long process flow, environmental pollution, irregular product shape, wide particle size distribution, and serious particle agglomeration.

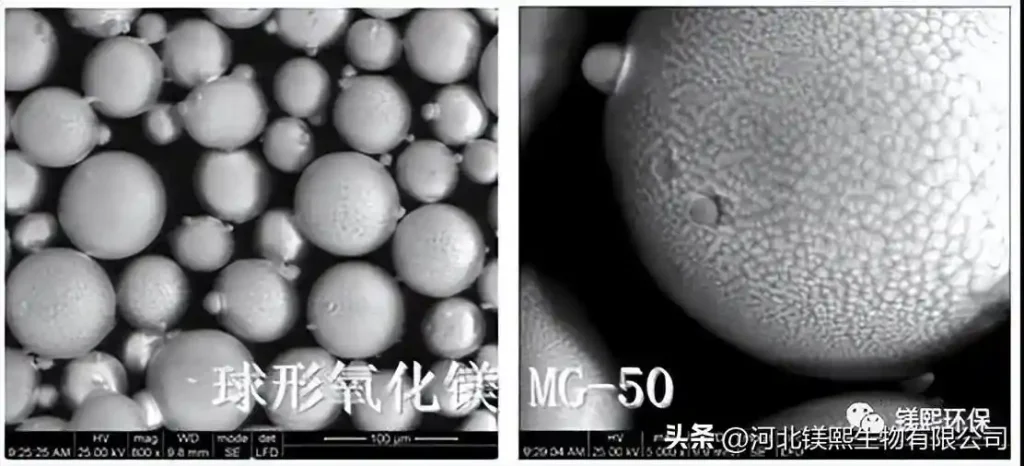

In recent years, magnesium oxide powders with different morphologies can be prepared by preparing precursors with special morphologies such as rod-shaped magnesium carbonate, flake-shaped magnesium hydroxide, and block-shaped basic magnesium carbonate, followed by pyrolysis or calcination. Among them, spherical magnesium oxide has the characteristics of high reactivity and good stability, and has shown broad application prospects in the fields of catalysts, bactericides, thermal conductive fillers, wastewater treatment and pollutant adsorption.

The preparation of spherical magnesium oxide is mostly obtained by calcining spherical basic magnesium carbonate, spherical basic magnesium oxalate, and spherical magnesium hydroxide as precursors. In the preparation process, alkaline precipitants, sodium polyphosphate, polyacrylamide and other surfaces are required. Active agent, and obtain bird’s nest and spherical magnesium oxide structure through growth regulation of sheet structure. At present, there is still a lack of a convenient method for preparing spherical magnesium oxide. The preparation process and device development of spherical magnesium oxide are of great significance for improving resource utilization and developing new functional materials.