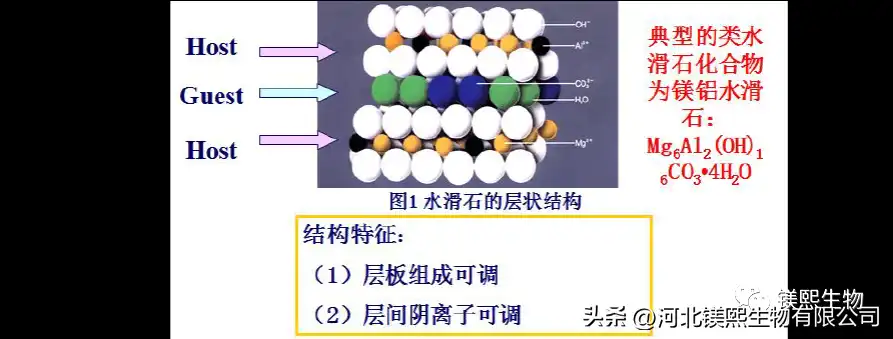

Hebei Messi Biology Co., Ltd. stated that by reacting soluble magnesium salts (reactive magnesium oxide, magnesium hydroxide) with aluminum salts and carbonate ions in a certain alkaline environment, water with high crystallinity and single crystal form can be produced. Talc. The production method is simple and easy, and the conditions are easy to control, which is conducive to the promotion of industrialization in the future.

Through a large number of experiments, the influence of factors such as the source of raw materials, temperature, reaction time, pH value, and the ratio of Mg/Al on the structure and properties of synthetic hydrotalcites were discussed. production needs. The surface treatment of hydrotalcite was carried out with anionic surface treatment agent sodium oleate, and the effects of the dosage of sodium oleate, temperature and pH value of the treatment environment on the treatment effect were studied. Through surface treatment, the agglomeration of hydrotalcite particles and the compatibility with polymer matrix are better improved. Taking LLDPE/EVA blend as matrix resin, the performance of the composite system of hydrotalcite and matrix resin was studied. The experimental results show that hydrotalcite can significantly improve the flame retardancy of the matrix resin.

Hebei Messi Biology Co., Ltd. stated that hydrotalcite has relatively high requirements for heavy metals and impurities, so the magnesium nitrate used in the initial experiment was abandoned and replaced by magnesium hydroxide or magnesium oxide. Magnesium hydroxide is a very fine chemical raw material with a uniform particle size distribution. It is recognized as a low-smoke, halogen-free and environmentally friendly flame retardant. It is widely used. The preparation method of hydrotalcite needs to be added to magnesium hydroxide . The content of magnesium hydroxide in hydrotalcite is about 60%, which is mainly used to extract magnesium element and is the basic raw material for synthetic hydrotalcite. Since hydrotalcite will be applied in specific industries, the particle size and whiteness requirements of magnesium hydroxide are relatively high, and iron, manganese and black spots must be controlled within a certain range.