Magnesium oxide is a high-performance chemical material with excellent chemical inertness, heat resistance, insulation and thermal conductivity. Especially its good high temperature oxidation resistance and moderate alkalinity make it widely used in many fields. In addition, the oxygen vacancies and single electrons in magnesium oxide also endow it with strong electrophilicity, which provides an important basic condition for its application.

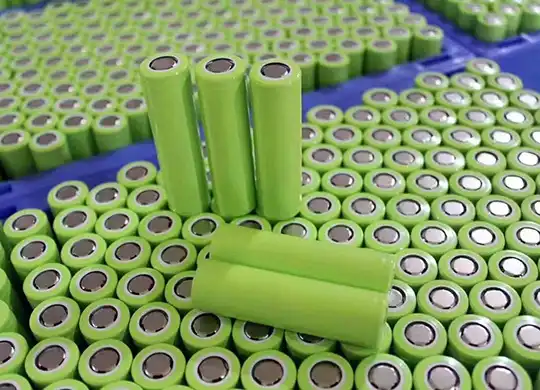

Among them, the application of magnesium oxide in the battery industry is worthy of our attention and research. Nano-magnesium oxide is often used in battery materials to improve the cycle and charge and discharge times of the battery and prolong the service life of the battery. This is because nano-scale magnesium oxide is a new type of nano-material, which has obvious small size, large surface effect, quantum size effect and macroscopic tunnel effect. After the surface is modified, there is no agglomeration phenomenon and better dispersion in the system. Therefore, it can give full play to the light, electricity, magnetic field, heat, and quantum effects of nano-magnesia particles, and greatly improve the performance of products added with nano-magnesia. Taking lithium batteries as an example, let’s learn about the application status in detail.

1. Added in the positive electrode material

The addition of nano-magnesium oxide in positive electrode materials has the characteristics of low price, high energy and safety. It is not only suitable for small and medium-sized polymer, colloid and liquid lithium-ion batteries, but especially suitable for high-power power batteries. Magnesium-doped lithium-iron-manganese phosphate is prepared by solid-state reaction with nano-magnesium oxide as a conductive dopant, which further produces a nanostructured positive electrode material with an electrical conductivity of 10-2 S/cm and an actual discharge capacity of 240mAh/ g.

2. Added in the negative electrode material

The high-capacity tin composite negative electrode material for lithium-ion batteries is selected to add 10 to 100 g/L of insoluble solid particles such as magnesium oxide with a diameter between 0.05 and 10 microns; the nickel-solid particle-tin composite negative electrode material prepared by this formula is used as lithium The ion battery negative electrode has high specific capacity, high initial charge and discharge efficiency, and stable cycle performance.

3. Preparation of electrode pH regulator

Nano magnesium oxide can be used as an alkali solution of a pH regulator and a kind of ammonia solution as a complexing agent are added to a mixed aqueous solution containing cobalt salt and nickel salt to co-precipitate Ni-Co composite hydroxide. The specific steps are: adding lithium hydroxide to the composite hydroxide, heat-treating the mixture at 280-420°C, and then heat-treating the product obtained in the above steps at 650-750°C. When this lithium composite oxide is used as an anode active material, a high capacity lithium ion secondary battery can be obtained.

In addition, the nano-magnesium oxide of Hebei Messi Biology Co., Ltd. is also widely used in zinc-nickel batteries, high-chloride zinc batteries, cadmium-nickel batteries and other fields, injecting powerful energy into the battery industry!

How much for the nano magnesium oxide?