With the rapid development of the national economy and the increasing awareness of environmental protection, sewage treatment has not only become the focus and difficulty of comprehensive water environment improvement in China, but also directly related to people’s health and sustainable development of the country. Among many treatment methods, the adsorption method has been widely used due to the advantages of simple operation, low cost and environmental friendliness. Its treatment effect (processing capacity and treatment speed) mainly depends on the chemical composition and pore structure of the adsorption material. The controllable preparation of excellent pore structure, high-efficiency and low-cost adsorption materials and their adsorption behavior research are of great significance and practical application value for the efficient treatment of sewage in China.

In comparison, magnesium oxide adsorption materials have the advantages of abundant sources, low cost, and rich surface active sites, and have been applied in the treatment of printing and dyeing industrial wastewater, heavy metal wastewater, and domestic sewage, but have disadvantages such as low specific surface area and wide pore size distribution. This greatly limits its adsorption performance. Based on the acid-base duality and ammonia slow-release characteristics of aluminum hydroxide, by regulating the release of ammonia during the formation of magnesium carbonate, the precursor of magnesium oxide, and using the dissolution mechanism of aluminum hydroxide generated at low pH under high pH conditions, the oxidation can be regulated. The pore structure of magnesium adsorption materials; using the organic dye methyl orange (MO) and the heavy metal lead ion (Pb2+) as probes, the influence of the pore structure of magnesium oxide adsorption materials on the adsorption performance of the two is discussed in detail, so as to reveal the pore structure of magnesium oxide The structure-effect relationship between adsorption performance and adsorption performance provides a scientific basis for the pore structure design and controllable preparation of high-efficiency magnesium oxide adsorption materials.

The key contents and achievements of the paper are as follows:

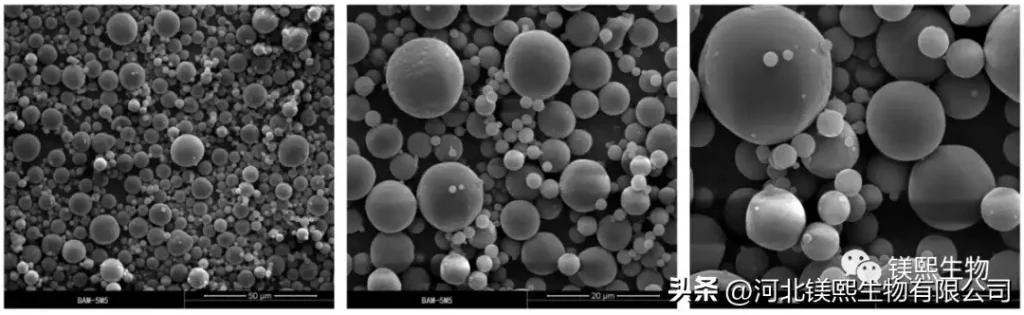

(1) Using magnesium chloride as the magnesium source and urea as the ammonia slow-release precipitant, the cubic magnesium carbonate precursor was controllably prepared by hydrothermal method, and the cubic magnesium oxide adsorption material with high specific surface area was prepared by roasting in air atmosphere, and its Adsorption performance on MO. The research results show that the specific surface area of the prepared adsorption material is 182m2/g, and the average pore size is between 6 and 8nm; the adsorption behavior of the adsorption material to methyl orange follows the pseudo-second-order kinetic equation and the Freundrich adsorption isotherm equation, The adsorption equilibrium is reached in about 10 minutes, and the maximum equilibrium adsorption capacity is above 3000 mg/g, which has excellent adsorption performance.

(2) Using magnesium chloride and aluminum chloride as magnesium source and aluminum source, urea as ammonia slow-release precipitant and aluminum hydroxide template dissolving agent, the magnesium carbonate precursor was prepared by hydrothermal method (180 ° C), and passed in air The atmosphere was roasted at 550℃ to form a straight-through mesoporous magnesium oxide adsorption material, and the adsorption behavior and mechanism of the adsorption material on MO and Pb2+ were discussed. The research results show that by adjusting the ratio of magnesium to aluminum, wheat spike-shaped magnesium oxide with high specific surface area and rich straight-through pore structure can be prepared under control; the specific surface area of the adsorption material can reach 136m2/g, and the average pore diameter is between 5 and 8nm; The adsorption process of the adsorption material for methyl orange and lead ions follows the pseudo-second-order kinetic equation and the Langmuir adsorption isotherm equation. The maximum adsorption capacity for methyl orange is 5483 mg/g, and the maximum adsorption capacity for lead ions is 2359 mg/g.

(3) Magnesium chloride and aluminum chloride are used as magnesium and aluminum sources, urea is used as ammonia slow-release precipitant, and surfactant cetyltrimethylammonium bromide (CTAB) and cetyltrimethylchloride are used Ammonium chloride (CTAC) was used as the morphology control agent, and two kinds of wheat spike-shaped magnesium oxide adsorption materials could be prepared by hydrothermal method and roasting method, and its adsorption performance on methyl orange was investigated in detail. The research results showed that the introduction of surfactant did not have a great impact on the morphology of the adsorption material; the specific surface area of wheat ear-shaped magnesium oxide after adding CTAB increased to 171m2/g, and the average pore diameter was 6.31nm. The adsorption process of the base orange followed the pseudo-second-order kinetic equation and the Freundrich adsorption isotherm equation, the equilibrium time was shortened to 10 minutes, and the maximum equilibrium adsorption capacity was 3353mg/g; the specific surface area of wheat spike-shaped magnesium oxide increased to 166m2 after adding CTAC /g, the average pore size is 5.55nm, the adsorption process of the adsorption material to methyl orange follows the pseudo-second-order kinetic equation and the Langmuir adsorption isotherm equation, the equilibrium time is shortened to 10min, and the maximum equilibrium adsorption capacity is 3518mg/g.