Hebei Messi Biology Co., Ltd. stated that in recent years, magnesium hydroxide has received widespread attention at home and abroad as a flame retardant. Compared with halogen flame retardants, magnesium hydroxide can not only improve the flame retardant effect of materials, but also has no smoke and halogenation. Toxic gases such as hydrogen are generated. When the content of magnesium hydroxide flame retardant in the low-density polyethylene system is increased to more than 50%, the material has good flame retardant effect. However, adding too much magnesium hydroxide flame retardant will seriously affect the mechanical properties and processing properties of the polymer. At the same time, due to the strong hydrophilicity and oil repellency of the surface of the magnesium hydroxide material, there will be a gap between it and the polymer material. The compatibility is poor and agglomeration is prone to occur in the matrix material. Therefore, improving the compatibility between the flame retardant and the polymer matrix through modification can make the flame retardant particles more uniformly dispersed in the matrix material, and the same flame retardant effect can be achieved while reducing the amount of flame retardant.

Studying the effect of stearic acid modified magnesium hydroxide on the flame retardant properties of polyethylene, it was found that when the flame retardant content is 20%, the system has good comprehensive properties. Studies have found that adding a large amount of magnesium hydroxide flame retardant will cause the mechanical properties of the material to deteriorate, while adding surface treatment agents can significantly improve the elongation at break of flame-retardant polyethylene. However, with the addition of surface treatment agents, the flame retardant performance of the system is reduced.

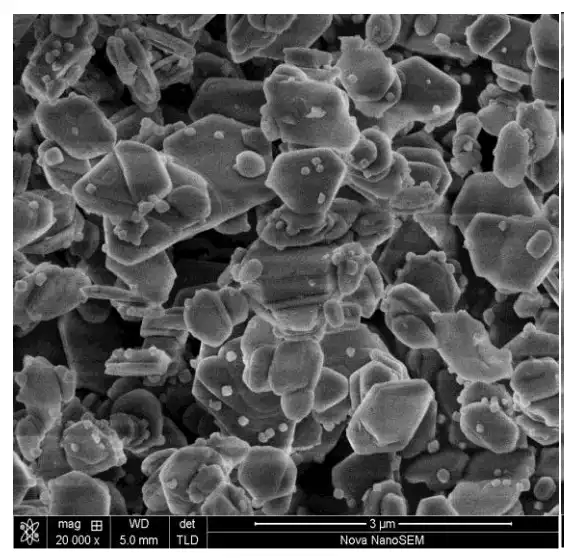

The effect of factors such as surface modification of ultrafine magnesium hydroxide filler and the amount of hydroxyl silicone oil on the mechanical properties of high-density polyethylene was studied. It was found that high filling amounts of fillers caused a significant decrease in the mechanical properties of the material, especially when the filler amount reached 70 parts. , the material shows obvious brittle tensile fracture behavior. Magnesium hydroxide modified by silane coupling agent and titanate can improve the tensile strength of the material and has less impact on the elongation at break.

Aminosilane coupling agent and alkylsilane coupling agent were used to modify magnesium hydroxide flame retardant, and linear low-density polyethylene was used as the base material to prepare low-density polyethylene/magnesium hydroxide flame retardant materials, and the modified hydrogen was investigated. The effects of magnesium oxide on the mechanical properties, flame retardant properties, thermal stability and electrical properties of low-density polyethylene composite specimens. The results show:

(1) As the dosage of magnesium hydroxide flame retardant increases, the mechanical properties of low-density polyethylene decrease significantly. At the same dosage, the effect of alkyl silane coupling agent modified magnesium hydroxide on the mechanical properties of low-density polyethylene materials is greater. Small.

(2) Magnesium hydroxide flame retardant significantly improves the flame retardant properties of low-density polyethylene. Due to the presence of nitrogen, aminosilane coupling agent modified magnesium hydroxide has a more obvious effect on improving the flame retardant properties of low-density polyethylene.

(3) Magnesium hydroxide inorganic particles significantly reduce the electrical properties of low-density polyethylene. Since amino groups are more polar than alkyl groups, alkyl silane coupling agent-modified magnesium hydroxide flame-retardant low-density polyethylene has better electrical properties.

(4) Alkyl silane coupling agent modified magnesium hydroxide has better compatibility with low-density polyethylene. When the addition amount is 70 parts, the heat release curve of the material shows an obvious broad peak, and its mechanical properties The performance and electrical properties decrease to a small degree. At this time, the tensile strength is 10.5MPa, the elongation at break is 350%, the dielectric constant is 2.8~2.9, and the volume resistivity is 5×1013Ω·m.