1. Adsorption:

Physical adsorption: The micropores and pore structures on the surface of magnesium carbonate particles provide a large number of adsorption sites, allowing them to physically adsorb organic substances, heavy metal ions, impurity particles, etc. in water. These micropores and pore structures have large specific surface areas, which increase the effectiveness and capacity of adsorption.

Chemical adsorption: The surface of magnesium carbonate has certain chemical activity, such as hydroxyl (-OH) and other functional groups, which can undergo chemical adsorption reactions with pollutants in water. This chemical adsorption may include hydrogen bonds, covalent bonds, etc., allowing pollutants to be stably adsorbed on the surface of magnesium carbonate.

2. Precipitation:

Carbonation reaction: Magnesium carbonate can react with alkaline components in water (such as calcium ions, magnesium ions, etc.) to form carbonate precipitation. This process helps soften the water, reduce the hardness in the water, avoid the formation of scale, and protect water pipes and equipment.

3. Adsorption kinetics:

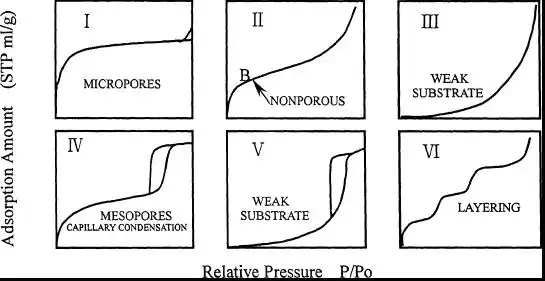

Langmuir adsorption isotherm: The adsorption behavior of magnesium carbonate can be described by Langmuir adsorption isotherm. The Langmuir model assumes that molecules adsorbed on a solid surface are independent between adsorption sites and that the formed monolayer adsorption has a saturation point. This model can help understand the changes in magnesium carbonate adsorption performance and adsorption capacity.

4. Regeneration and recycling:

Thermal regeneration: Magnesium carbonate will gradually become saturated during the adsorption process and needs to be regenerated regularly. Commonly used regeneration methods include thermal regeneration, which involves heating magnesium carbonate particles to release adsorbed pollutants and restore their adsorption capacity.

Recycling: Adsorbed saturated magnesium carbonate particles can usually be regenerated or recycled through physical or chemical methods to reduce processing costs and reduce resource consumption.

By deeply understanding the adsorption and precipitation mechanisms of magnesium carbonate, we can better understand its application in the field of water purification, thereby more effectively improving water quality and protecting the environment.