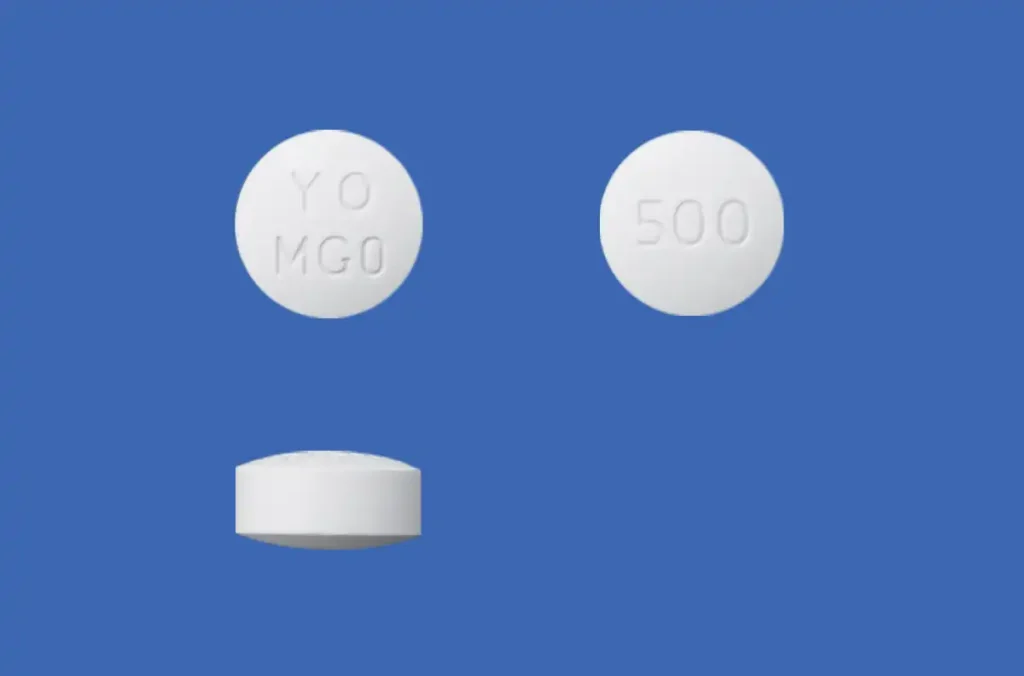

La production de comprimés de médicaments peut être utilisée dans la granulation humide et la granulation sèche et la compression, dans le médicament à l’eau, l’instabilité thermique avec hygroscopicité ou l’utilisation de la méthode de compression directe de faible liquidité lors de l’utilisation de la granulation sèche et de la compression, comprimés pressés d’oxyde de magnésium, c’est-à-dire l’utilisation de la granulation sèche et de la compression.

La qualité des comprimés lors du pressage des comprimés dépend principalement de la nature des matières premières et auxiliaires, de la pression, de l’humidité, du liant, de l’agent de désintégration, etc. Lorsque les matières premières et auxiliaires et les paramètres de pressage ne sont pas idéaux, des lobes, des perforations collantes, une désintégration lente, une différence excessive de poids des comprimés, des taches de couleur, des piqûres et d’autres phénomènes anormaux peuvent se produire lors du pressage des comprimés. Lorsque l’oxyde de magnésium brut produit par le procédé existant pour la compression à sec est utilisé, les comprimés se cassent lors des essais de pression, ce qui peut être dû à une sélection inappropriée du liant, à une quantité excessive de fines de matières premières et à une pression trop élevée.

Afin d’ajuster le processus de production et les paramètres de l’oxyde de magnésium à faible teneur en plomb pour garantir qu’il puisse passer le test de pression des comprimés lorsqu’il est appliqué dans le pressage de comprimés, Messi Biology a développé des granulés bruts d’oxyde de magnésium à faible teneur en plomb. Selon les caractéristiques de production de l’oxyde de magnésium à faible teneur en plomb, le processus de granulation de l’oxyde de magnésium à faible teneur en plomb a été ajusté pour réduire la teneur en particules fines, augmenter la capacité de liaison des particules, éliminer les phénomènes anormaux tels que les taches de couleur et les marques de piqûres, et éviter la compression ultérieure des comprimés, qui ne sont pas étroitement liés et se fragilisent facilement pour provoquer une fracture. La préparation finale est conforme aux particules brutes d’oxyde de magnésium à faible teneur en plomb pour le pressage à sec, et le processus est stable.

L’oxyde de magnésium à faible teneur en plomb de Messi Biology ne produit pas de taches de couleur, de piqûres et d’autres anomalies lors de l’utilisation du pressage à sec, la qualité de l’oxyde de magnésium à faible teneur en plomb répond à la norme de contrôle interne de l’entreprise, le volume spécifique apparent est d’environ 1,20 ml/g, aucune couleur anormale lors du pressage, et le comprimé passe le test de pression et ne peut garantir une fracture sous 260 N.