Hebei Messi Biology Co., Ltd. stated that nano-magnesium oxide is a new multi-functional fine inorganic material with important industrial application prospects and huge economic potential, especially different crystalline nano-magnesium oxide in microelectronics and military stealth materials. Applications in other fields have attracted more and more attention at home and abroad. Since the size of nanoparticles is much smaller than the wavelength of infrared and radar waves, their specific surface area is 3 to 4 orders of magnitude larger than that of conventional coarse powder, making the transmittance and absorption rate of nanomaterials to infrared rays much greater than that of conventional materials. Infrared detectors and radar The intensity of the reflected signal is greatly reduced, playing a stealth role.

Scholars at home and abroad have paid enough attention to nanomaterials. After decades of development, nanomaterials have made significant progress. However, there is little relevant information on in-depth research on the performance of nanomagnesium oxide. If the research on the properties of nano-magnesium oxide materials can be strengthened, it will be of great significance to improve the added value of deep processing products of magnesite resources and promote the efficient development and utilization of magnesite resources.

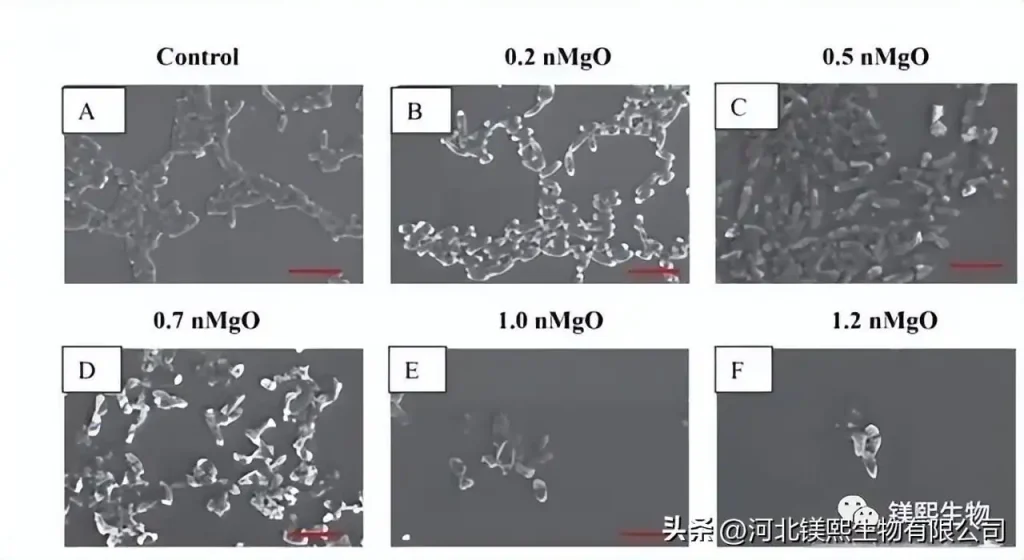

In this article, liquid phase precipitation thermal decomposition method was used to prepare flake nano-magnesium oxide. The types and dosages of crystal form control agents were compared. Through characterization and analysis of scanning electron microscopy and X-ray diffraction, the effect of crystal form control agents on the shape of nano-magnesium oxide was studied. appearance and dispersion effects. By studying the effects of different carboxyl and hydroxyl crystal form control agents on the morphology of nanoscale magnesium oxide prepared by liquid phase precipitation thermal decomposition method, the following conclusions were drawn:

1) Nano-magnesium oxide prepared by using monocarboxylic and monohydroxyl crystal form control agents is spherical and has serious agglomeration;

2) Polycarboxyl and polyhydroxy crystal form control agents are beneficial to the distribution of nano-magnesium oxide particles along the sheet;

3) Ethylenediaminetetraacetic acid can improve the dispersion of nano-magnesium oxide particles. When its dosage is 6 mg/L, it is beneficial to the distribution of nano-magnesium oxide particles along the sheet shape, and the magnesium oxide grain size is only 26.13nm;

4) When a small amount of polyethylene glycol is added, the prepared nano-magnesium oxide has a better dispersion effect. When the dosage is 1.2 mg/L, it is beneficial to generate flaky nano-magnesium oxide particles.