Hebei Meixi Biological Co., Ltd. stated that in order to prevent the molten electrolyte from flowing under hot battery conditions, it is necessary to add a flow inhibitor to make a spacer powder before use. The flow inhibitor should not react with metal lithium. The commonly used flow inhibitor is magnesium oxide.

On the basis of ensuring the original basic characteristics of the polyolefin microporous diaphragm, magnesium oxide can endow the diaphragm with high heat resistance and reduce the thermal shrinkage of the diaphragm, thereby more effectively reducing the internal short circuit of the lithium-ion battery and preventing the internal short circuit of the battery. thermal runaway of the battery.

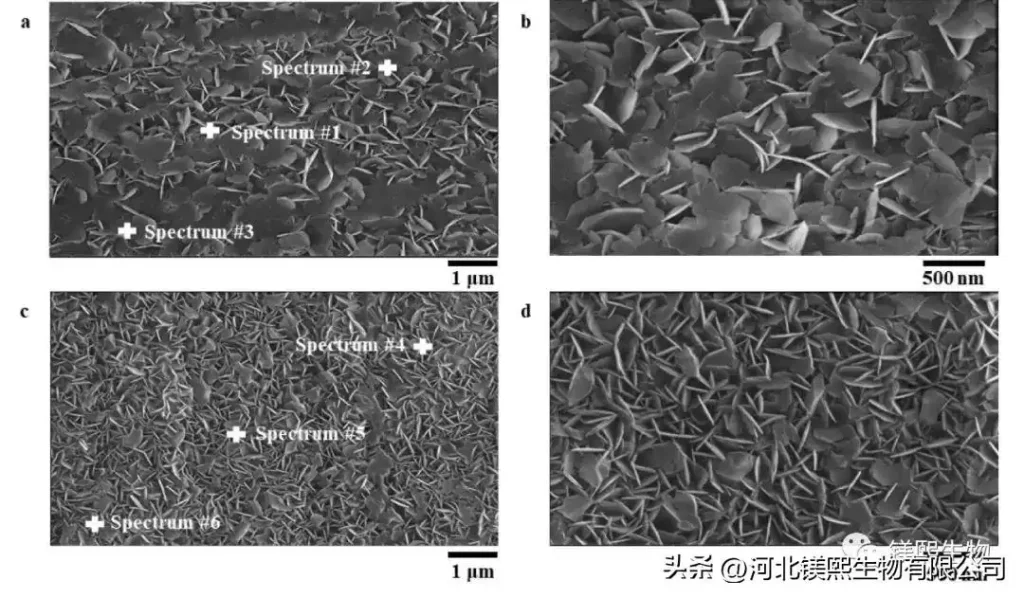

A method for preparing battery-grade nano-magnesia, the method for preparing battery-grade nano-magnesia comprising the following steps: dispersing a solid compound of magnesium, an organic dispersant and industrial alcohol in water to form a suspension; dispersing the suspension The turbid liquid is obtained into a dispersed slurry, and the dispersed slurry is pulverized and ground; the pulverized and ground slurry is collected after centrifugation, and the filter cake is dried to obtain a magnesium-containing precursor powder; roasting the magnesium-containing precursor powder After cooling, magnesium oxide with different particle sizes is obtained, and the magnesium oxide with different particle sizes is shaken and sieved to obtain battery-grade nano magnesium oxide.

The preparation method of battery-grade nano-magnesia adopts the technology of “wet crushing-high temperature roasting-vibration screening” to produce battery-grade nano-magnesia. The preparation method of battery-grade nano-magnesia has simple preparation process and low cost. The equipment requirements are low, and the prepared magnesium oxide has high purity and small particle size.