Hebei Messi Biology Co., Ltd. stated that in recent years, some metal oxides or metal hydroxides have attracted people’s attention because of their low cost, environmental protection and excellent adsorption properties. Among them, magnesium oxide (MgO) has the characteristics of large specific surface area, rich pore structure, many surface active sites, strong adsorption capacity, and wide application range, and has become one of the most promising metal oxide adsorbents for treating water pollutants.

For example, using magnesium nitrate and urea as raw materials and ethanol as solvent, flower-shaped magnesium oxide with high specific surface area was prepared by microwave-assisted solvothermal method, and showed excellent removal efficiencies for Pb and Cd, with maximum adsorption amounts of 1980 and 1500 mg g-1, they also proposed an adsorption mechanism of cation exchange between Mg ions from magnesium oxide and Pb or Cd. Magnesia nanoparticles were prepared by the sol-gel method for the removal of Cd and Pb in aqueous solution (the maximum adsorption capacity was 2294 and 2614 mg g-1, respectively), and the competitive adsorption of the two ions was studied, and the results showed that the adsorption The order of preference is Pb>Cd. The hexagonal mesoporous MgO nanosheets have a specific surface area of up to 182m2·g-1 and are used to remove Ni from aqueous solution with a maximum adsorption capacity of 1684.25mg·g-1. On this basis, it is of great research value and economic significance to study magnesium oxide adsorbents with higher adsorption performance, lower preparation cost and difficulty.

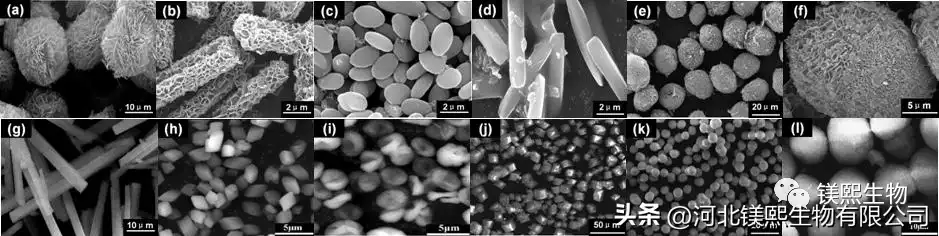

Based on this, a method for preparing mesoporous reticular magnesia using abundant natural hydromagnesite as a raw material. Generally, the mesoporous network structure has a rich pore structure, high specific surface area, and can provide a large number of surface active sites, which is an excellent structure with good adsorption characteristics. Therefore, in order to verify whether the special structure of magnesium oxide has excellent adsorption performance, taking Pb(II) as an example, the effect of magnesium oxide dosage, adsorption time, adsorption temperature and pH on the adsorption of lead ions in simulated wastewater by magnesium oxide was systematically studied. The influence of performance and adsorption mechanism, and the adsorption effect of magnesium oxide adsorbent on multi-component ions in solution was investigated.

Hebei Messi Biology Co., Ltd. said that using natural hydromagnesite as raw material, a high specific surface area mesoporous network magnesium oxide was prepared by a simple method of “calcination-hydration-calcination”, and no reagents were added during the experiment. The effects of magnesium oxide dosage, adsorption time, adsorption temperature and pH on the adsorption performance of magnesium oxide in simulated wastewater were systematically studied, the adsorption mechanism was revealed, and the adsorption effect of magnesium oxide on various ions was investigated. The results showed that: The magnesium oxide adsorbent has a high specific surface area of 188 m2 g-1, a high pore volume of 0.85 cm3 g-1, and an average pore diameter of 12.33 nm. The adsorption kinetics and isotherm data are highly consistent with the pseudo-second-order model and the Langmuir model. The results are consistent, indicating that the heavy metal ions are chemisorbed on the MgO monolayer.

The mesoporous network structure of MgO exhibits high adsorption performance for Pb(Ⅱ), with a maximum adsorption capacity of 7431.5 mg·g-1, which is much higher than that of other reported MgO-based adsorbents, and the lead removal rate is as high as More than 99.8%. The adsorption mechanism of mesoporous network magnesium oxide is mainly caused by the ion exchange between hydroxyl functional groups and Mg(Ⅱ) and heavy metal ions on the surface of magnesium oxide. In addition, the magnesium oxide can adsorb various ions at the same time, and has excellent adsorption properties for Cd, Cr, Ni, As, Co, P, Se, Be, Bi, Cu, Fe, Mn, V, Zn, and Al ions.