Hebei Messi Biology Co., Ltd. stated that magnesium hydroxide flame retardant is colorless, non-toxic, odorless, non-corrosive and is a green and environmentally friendly polymer material additive. Magnesium hydroxide with good flaky or fibrous crystal form can be better matched with the raw materials without affecting the physical properties such as the strength of the raw materials, and greatly improves the flexural strength and elongation of polymer materials. Therefore, magnesium hydroxide flame retardants with special morphology have better properties and wider applications.

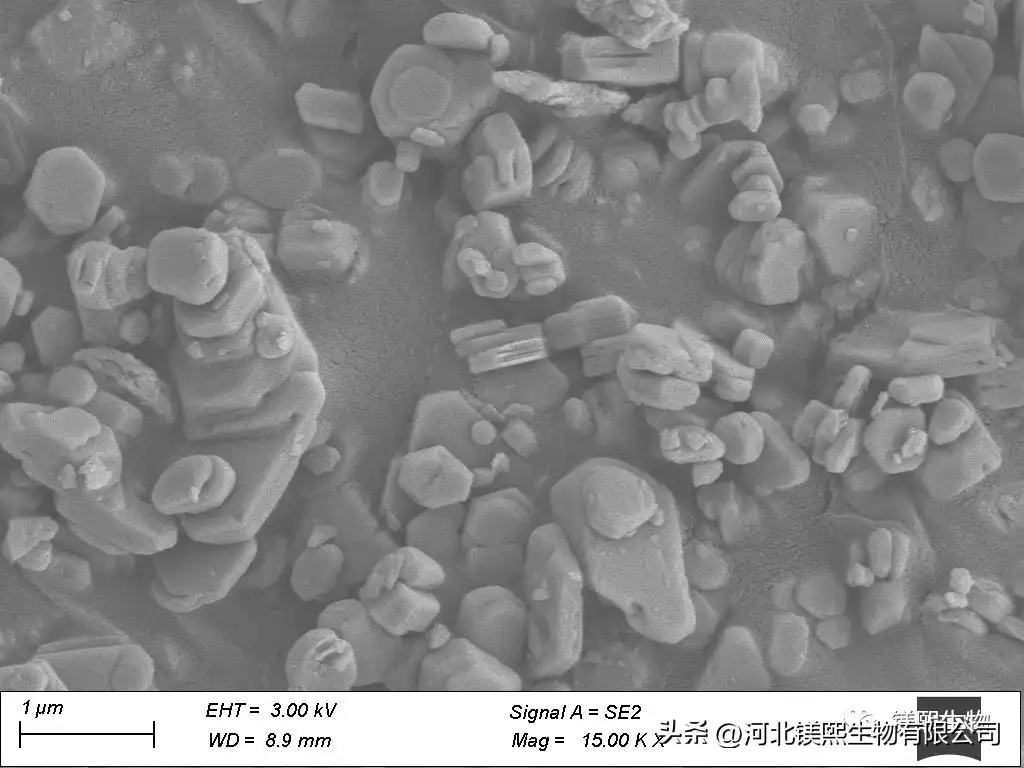

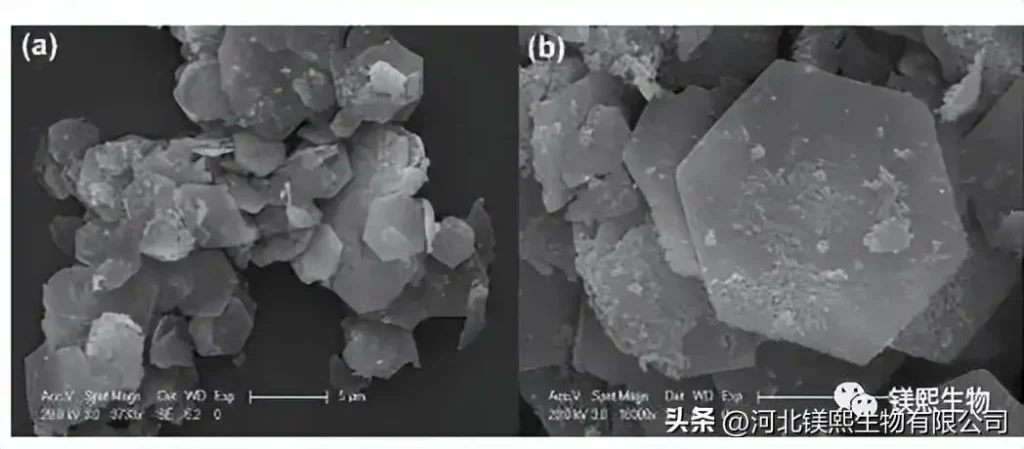

Liaoning is rich in brucite resources, accounting for about two-fifths of the total domestic reserves. Brucite has a simple chemical composition and low decomposition temperature. Magnesium hydroxide is prepared from brucite as raw material. The raw material is abundant. During the processing, there is no pollution to the environment and low energy consumption. Therefore, using Kuandian brucite as raw material and applying magnesium chloride method and magnesium oxide method respectively to prepare ultrafine magnesium hydroxide with special morphology under hydrothermal conditions has certain theoretical and practical significance. After XRD testing, the product purity and degree of crystallization are very high. Using scanning electron microscopy, the product was found to be in the shape of hexagonal flakes or whiskers, with complete crystal form and uniform particle size. The particle size reached the submicron level. The whisker diameter was tens of nanometers and the length was 2~5 μm. After analysis and research, the following conclusions are reached:

Magnesium chloride method

1) The preparation of magnesium hydroxide crystal precursor – basic magnesium chloride is one of the necessary prerequisites for producing magnesium hydroxide products with high crystallinity, uniform particles and good dispersion.

2) Influencing factors: Temperature significantly affects the growth rate of magnesium hydroxide crystals. Magnesium hydroxide crystals prepared at 140°C are the most ideal. The outer radii of regular hexagonal crystals are all around 0.4 μm; the stirring speed affects the growth rate of magnesium hydroxide crystals.

According to the growth direction of magnesium hydroxide crystals, when the speed is about 250r/min, smooth and uniform magnesium hydroxide whiskers can be produced; in addition, in the range of 100~600r/min, the magnesium hydroxide crystals all crystallize in the form of flakes; Within a certain range, the filling degree is inversely proportional to the thickness of the magnesium hydroxide hexagonal flake crystals; Reagent 1 effectively controls the size of the magnesium hydroxide crystal particles and ensures the integrity of its shape; Reagent 2 and Reagent 3 The effect is similar to that of Reagent 1, but the effect is slightly worse.

Magnesium oxide method

1) Influencing factors: Reagents 1 and 3 effectively control the size of magnesium hydroxide crystal particles and the integrity of the crystal form; reagent 4 promotes the one-dimensional growth of magnesium hydroxide crystals to a certain extent; the solution concentration mainly affects the growth direction of the crystal.

2) The magnesium hydroxide product obtained by the magnesium chloride method and the magnesium oxide method has a high degree of crystallization, but the purity of the product obtained by the magnesium chloride method is higher.