Nano-magnesium oxide is a new type of high-function fine inorganic material. Nano-magnesium oxide is widely used in electronics, catalysis, ceramics, oil products, coatings and other fields. Flame retardants for chemical fiber and plastic industries; medium and high temperature dewatering agents for silicon steel sheet production, advanced ceramic materials, electronic industry materials, binders and additives in chemical raw materials; radio industry high-frequency magnetic rod antennas, magnetic device fillers, insulating materials Filling and various carriers; refractory fibers and refractory materials, magnesia-chrome bricks, fillers for heat-resistant coatings, high temperature resistance, insulation resistance instruments, electricity, cables, optical materials and steelmaking; electrical insulator materials, manufacturing crucibles, furnaces, insulating conduits (tubular components), electrode rods, electrode sheets.

At present, the methods for preparing nano-magnesia mainly include gas-phase method, liquid-phase method and solid-phase method. The gas phase method is to use magnesium vapor and oxygen for gas phase reaction to produce rectangular or cubic nanocrystalline magnesium oxide; the liquid phase method is to select one or more suitable soluble metal salts, and prepare the solution according to the prepared material composition. Make each element in an ion or molecular state, and then select a suitable precipitant or use evaporation, sublimation, hydrolysis, etc. to uniformly precipitate or crystallize the metal ions, and finally dehydrate or heat the precipitate or crystal to obtain the required Material powder; solid-phase method can be divided into mechanical pulverization method and solid-phase reaction method according to its processing characteristics. The mechanical pulverization method is to use a crusher to directly grind the raw materials into ultra-fine powder. The solid-phase reaction method is to fully mix the metal salt or metal oxide according to the formula, and then calcine after grinding to produce a solid-phase reaction, and obtain ultra-fine powder directly or after grinding. However, the nano magnesium oxide prepared by the above method also has problems such as large particle size and uneven distribution, easy aggregation of particles, poor dispersibility and the like.

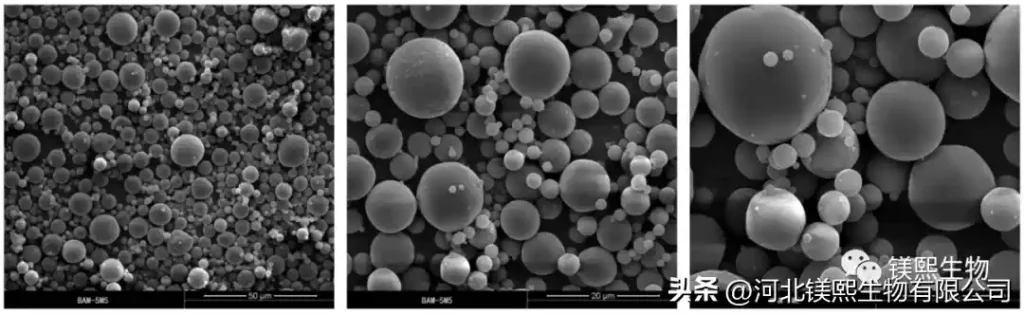

Tibet Mag has provided a method that uses magnesium chloride as the source of magnesium and citric acid as the complexing agent to slowly release magnesium ions in view of the current disadvantages of uneven particle size distribution of nano-magnesia, easy agglomeration of particles, and poor dispersion. , with sodium hydroxide as precipitant, react to generate magnesium hydroxide precipitate, then use sodium dodecylbenzenesulfonate as surfactant, n-butanol as co-surfactant, dissolve in oily solvent n-hexane, and then mix with The mixed slurry is fully mixed and balanced to form upper and lower phases, and the upper layer of water-in-oil microemulsion is separated, and then sodium peroxide and concentrated sulfuric acid are used as dehydrating agents to dehydrate magnesium hydroxide to form spherical magnesium oxide under ultrasonic demulsification conditions , use dry ice to cool down the solution, and react with residual sodium hydroxide to generate sodium carbonate, and then filter, wash and dry to obtain spherical nano-magnesia. The nano-magnesia has good dispersion performance, and effectively solves the problem of uneven particle size distribution of the nano-magnesia and easy agglomeration of particles.