With the rapid development of my country’s mechanical and electrical industrialization, the entire market has put forward new requirements for silicon steel in special steel in terms of both quality and quantity, and there is also a huge gap. Therefore, domestic silicon steel sheet production is in a booming period, and silicon steel grade magnesium oxide, as an important insulating coating material for oriented silicon steel sheet production, is also facing important opportunities and challenges. Energy-saving and environment-friendly equipment is favored, and the requirements for transformers and motors are developing towards high-power miniaturization. The requirements for silicon steel sheets are developing in the direction of ultra-thin, high magnetic induction, and low energy consumption. In order to adapt to the current development situation, we have developed and realized the first generation of industrialized production in the past, and the second generation of silicon steel grade magnesium oxide has shown incompatibility, producing high magnetic induction oriented electrical steel (Hi-B) and low temperature oriented electrical steel Steel will require more demanding silicon steel grade magnesia.

Silicon steel grade magnesium oxide is specially used as high temperature annealing separator and insulating coating forming agent in the production of grain oriented silicon steel sheet.

The main function of silicon steel grade magnesium oxide in high temperature annealing of grain oriented silicon steel sheet:

- Prevent sintering of silicon steel sheets and coils (sheet thickness 035mm-0.25mm) in high temperature (1250°C, 24×7 hours) annealing.

- Remove S, P and other impurities in silicon steel.

- During high-temperature annealing, it reacts with SiO on the surface of the silicon steel to form a forsterite coating, which gives the silicon steel sheet insulation resistance and magnetic properties (coercive force), thereby improving the quality of the silicon steel sheet.

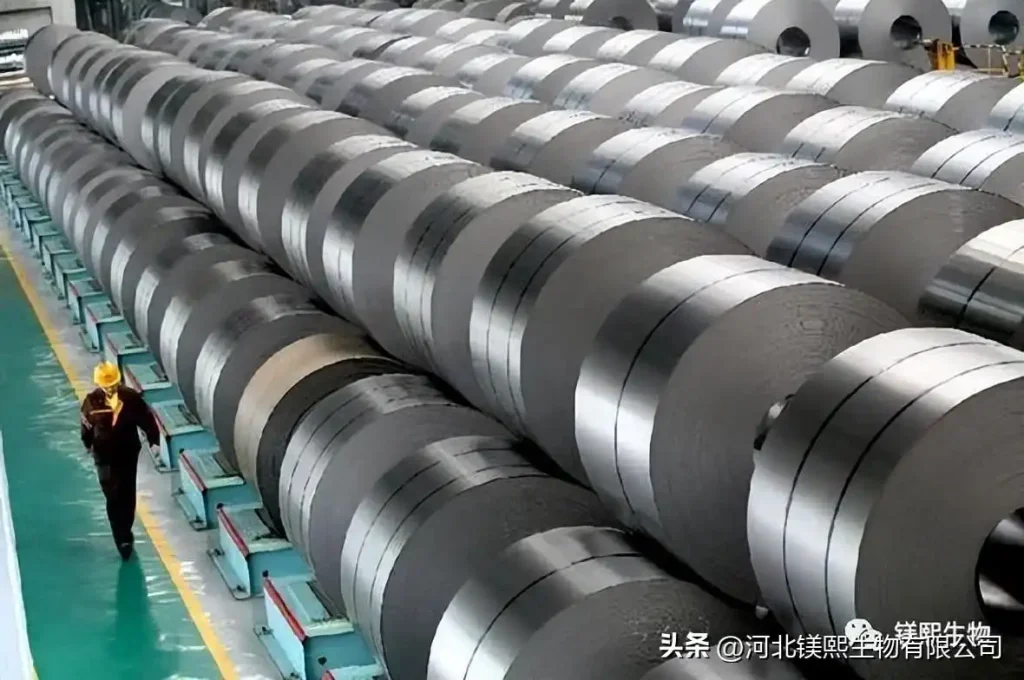

Oriented silicon steel sheet is the main material for manufacturing advanced transformers, generators, and motors. my country’s economic development has promoted the development of the electrical industry and driven the demand for silicon steel sheets. The country needs high-quality electrical equipment, so it needs high-quality silicon steel sheets, and high-quality silicon steel-grade magnesium oxide is a must for the production of high-quality grain-oriented silicon steel sheets.

At present, domestic magnesium oxide manufacturers lack reliable and mature production technology and research and development capabilities. As the output of grain-oriented silicon steel sheet production in my country is increasing year by year, the consumption of grain-oriented silicon steel grade magnesium oxide in my country is also increasing year by year, which increases with the gradual increase of the production capacity of grain-oriented silicon steel sheet in Wuhan Iron and Steel Co., Ltd. In 2010, the production capacity of grain-oriented silicon steel sheets of Wuhan Iron and Steel has reached 400,000 tons, and the required amount of silicon steel grade magnesium oxide (6~8kg of silicon steel grade magnesium oxide is required to produce each ton of grain-oriented silicon steel sheets) will reach about 2,800 tons.