Abstract

A method for preparing rod-shaped nanometer magnesium oxide, which belongs to the field of material technology and is carried out according to the following steps: (1) Dissolve soluble magnesium salt, precipitating agent sodium hydroxide and crystal form control agent as reaction raw materials in water to prepare a reaction solution; The crystal form control agent is ethylene glycol, starch, emulsifier OP10 or triethanolamine; (2) react the prepared reaction solution at 20-90°C and stirring conditions for 20-40 minutes, and the precipitate obtained is the precursor. ; (3) Calculate the obtained precursor at 550-750°C for 2-4 hours.

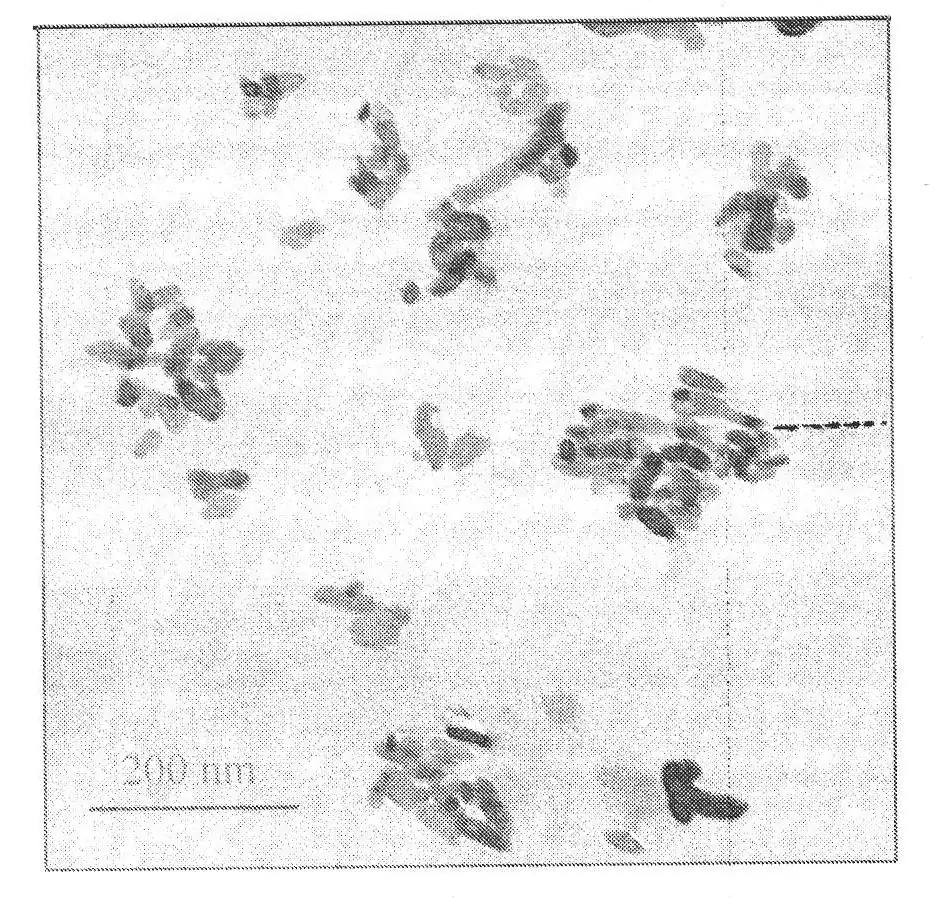

The method of the present invention obtains a loose precursor by selecting a crystal form control agent and controlling the precipitation conditions, and controls the calcination conditions to prepare rod-shaped nano-magnesium oxide; the particle size and aspect ratio of the obtained rod-shaped nano-magnesium oxide are controllable. This method has the advantages of easily available raw materials, simple process, and is suitable for industrial production. It has good application prospects in the field of infrared stealth material technology.

Description

Technical field

The invention belongs to the field of material technology, and particularly relates to a preparation method of rod-shaped nanometer magnesium oxide.

Background technique

Nano-magnesium oxide is a new type of high-functional fine inorganic material. In addition to having the properties and uses of ordinary magnesium oxide, because the particles enter the nanoscale, nano-magnesium oxide has surface effects, quantum size effects, volume effects, etc. shared by nanoparticles. In addition to the macroscopic quantum tunneling effect, it also has a series of properties that ordinary magnesium oxide does not have, thus opening up a series of new application fields. Nanoscale magnesium oxide has special properties such as heat, light, electricity, mechanics, and chemistry that are different from the bulk material. It has important application prospects and huge economic potential in industry. Infrared absorption is a type of stealth technology. Infrared stealth materials are a hot topic in current stealth technology research and have broad research prospects.

At present, there are many methods to prepare nano-magnesium oxide. Recent research results show that soluble magnesium salt is mixed with a precipitating agent, and then the shape of the crystal particles is controlled by surfactant, and the precipitation is made under stirring, ultrasonic or heating conditions, and then through Calcined to obtain nanometer magnesium oxide. In the existing methods, the morphology control of nanometers is mainly determined by the reaction time, reaction temperature, stirring conditions, and calcination temperature and time. The cost of the selected surfactants such as stearate is relatively high. What is more important is the control of nanometer morphology. There is no breakthrough effect in terms of the shape of magnesium oxide; nano-magnesium oxide of different shapes has different infrared absorption characteristics and is suitable for various infrared absorption ranges. How to choose more suitable surfactants and other auxiliary materials, and according to different Determining other process conditions for materials and preparing nano-magnesium oxide materials with controllable shapes and suitable for special requirements are currently urgent problems to be solved.

Contents of the invention

In view of the shortcomings in the existing nano-magnesium oxide preparation technology, the present invention provides a preparation method of rod-shaped nano-magnesium oxide. The purpose is to determine an optimized process route by selecting an appropriate crystal form control agent and using a low-cost and simple process. Methods to prepare rod-shaped nanomagnesium oxide.

The method of the present invention is carried out according to the following steps:

- Dissolve soluble magnesium salt, precipitant sodium hydroxide and crystal form control agent as reaction raw materials in water to prepare a reaction solution. The components of the reaction raw materials are 27-44% sodium hydroxide and 55-55% soluble magnesium salt by weight. 72%, crystal form control agent 0.1-2%, the amount of water is subject to dissolving all materials; the crystal form control agent is ethylene glycol, starch, emulsifier OP10 or triethanolamine.

- React the reaction solution at 20 to 90°C under stirring conditions for 20 to 40 minutes, with a stirring speed of 200 to 900 rpm, and the precipitate obtained is the precursor.

- Calculate the obtained precursor at 550-750°C for 2-4 hours to obtain rod-shaped nano-magnesium oxide.

The above-mentioned soluble magnesium salt is magnesium chloride or magnesium nitrate.

The above-mentioned rod-shaped nanomagnesium oxide has an aspect ratio of 1.26 to 1.42, a length of 38 to 75 nm, and a diameter of 27 to 53 nm.

The method of the present invention selects ethylene glycol, starch, emulsifier OP10 or triethanolamine as the crystal form control agent, and at the same time obtains a loose precursor by controlling the precipitation conditions, and then controls the calcination conditions to prepare rod-shaped nano-magnesium oxide; the rod-shaped obtained The particle size and aspect ratio of nano-magnesium oxide are controllable. The method of the present invention has the advantages of easily available raw materials, simple process, and is suitable for industrial production, and has good application prospects in the technical field of infrared stealth materials.