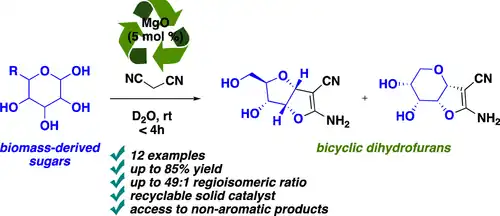

Hebei Messi Biology Co., Ltd. stated that the ratio of the oxide carrier plays an important decisive role in the appearance and performance of a single carbon nanoma. The FE-Co load is on the magnesium oxide carrier of different surface area, and the RFCCVD (radio frequency-catalytic chemical gas sedimentation method) is used to make methane heating to synthesize nanotubes. The crystallization of the product is improved, and the formation of amorphous carbon is also prevented.

Experiments show that the higher the surface area of the metal nanoparticles, the more conducive to forming nano -nanotubes with compact structure, narrow particle size distribution, and high purity. The large ratio and high pores make it easy Migration during the heat growth process of nanotubes; when the surface area of magnesium oxide is reduced, the active metal will gather on the carrier, which will adversely affect the diameter, knot nature and stability of the nanotuba. The surface area is a very important factor that controls the synthesis, appearance and micro -structural performance of nanotubes.

The activity and performance of the catalyst with magnesium oxide as the carrier. The uniform precipitation (HDP) method is used to deposit gold particles on the surface of magnesium oxide, and the precipitant is urea. Taking the hydrogen peroxide (TBHP) as the organic oxidant, the response temperature and time were 95 ° C and 0.5h, respectively. The activity of the AU/MGO catalyst was tested by the reaction system converted into a phenyldehyde into a benzaldehyde. The experimental process found that the preparation methods, gold content, and roasting temperature of catalysts are closely related to catalytic activity, catalytic efficiency, and relatively selectivity. With the increase in gold bearing (up to 0.1mmolag/g), the conversion rate and selectivity of the alcohol have also increased.

The research results also show that the optimal baking temperature of the AU/MGO catalyst transformed the best roasting temperature to the maximum extent of alcohol is 400 ° C, and the low catalytic activity of the ingredients obtained at low -temperature roasting (100 ° C or 200 ° C) may be due to the catalyst due to a catalyst. There is an incomplete decomposition of the golden front-drive body on the water or carrier; in turn, when the roasting temperature of AU/MGO rises to 400-900 ° C, the reaction yield is also reduced. As a result of 36nm, the size of the gold particles increased at the same time as the surface area decreased from 47m2/g to 34m2/g.

The carrier of magnesium oxide as a catalyst. In the CTAB/1-butanol/isolate/nitrate (CTAB-hexxial alkyl tritetroba) and other compounds, the 20%LAMNO 3 load is loaded through the micro emulsion method. On the surface of magnesium oxide, in order to change the interaction between Lamno3 and MGO, and the degree of interaction between the catalyst and its carrier, the following different methods are used to prepare catalysts:

(1) Synthesis of LaMnO3 and mgo (ME-Coprec) by co-precipitation method,

(2) Lamno3 (ME-1) The surface of the front body of the front body of the magnesium oxide precipitation,

(3) Synthesize Lamno3 and magnesium oxide front drives, and then mix. Experimental data found that only when the roasting temperature is 900 ° C, the synthesis method has an effect on the material of the material of the material (the procedure heating and restore) and the surface area of the surface. The shape of the TPR curve has not changed, which may be due to the disappearance of interaction between Lamno3 and MGO. The activity of Lamno3/MGO was tested by the 1.5%methane combustion experiment of 1.5%of the air. The result was found that the load catalyst showed higher activity than the separate Lamno3 oxide.