Silikonkautschuk weist hervorragende Eigenschaften wie hohe und niedrige Temperaturen, Witterungsbeständigkeit und Ozonbeständigkeit auf und wird in verschiedenen Bereichen der Volkswirtschaft häufig verwendet. Silikonkautschuk selbst ist jedoch entflammbar und brennt weiter, wenn er einem Feuer ausgesetzt wird, was seine Anwendung in der Elektronik, bei Drähten und Kabeln, in Automobilen, in der Luft- und Raumfahrt und in anderen Bereichen bis zu einem gewissen Grad einschränkt.

Um den Anwendungsbereich von Silikonkautschuk zu erweitern, ist die flammhemmende Modifikation zu einer der wichtigsten Forschungsrichtungen geworden. Die in den frühen Tagen verwendeten Flammschutzmittel waren brennbare Flammschutzmittel wie zehn Bromdilat, Chlorchlorid und andere phosphorhaltige Flammschutzmittel. Obwohl diese Flammschutzmittel eine gute flammhemmende Wirkung auf Silikonkautschuk haben, sind sie schädlicher für die Umwelt, da sie beim Verbrennen schädliche Gase freisetzen.

Gleichzeitig werden Magnesiumhydroxid und Aluminiumhydroxid beim Verbrennen ohne schädliche Gase freigesetzt. Die Verbrennungsrückstände verursachen keine Umweltverschmutzung. Daher wird es immer häufiger als umweltfreundliches Flammschutzmittel verwendet. Magnesiumhydroxid und Aluminiumhydroxid können jedoch nur dann eine signifikante flammhemmende Wirkung haben, wenn sie in großen Mengen verwendet werden, und eine große Menge Wasserstoffoxid kann die mechanischen und elektrischen Eigenschaften von Silikonkautschuk stark beeinträchtigen. Eine Oberflächenmodifizierung von Magnesiumhydroxid trägt dazu bei, seine Dezentralisierung in Silikonkautschuk zu erhöhen und seine Schnittstellenkompatibilität mit Silikonkautschuk zu verbessern, sodass Silikonkautschuk flammhemmend bleibt und gleichzeitig eine gute mechanische Leistung aufweist.

Nach der Zugabe von Magnesiumhydroxid in Silikonkautschuk steigt der extreme Sauerstoffindex an und steigt mit der Zunahme von Magnesiumhydroxid. Das im Silizium von Silizium verstreute Magnesiumhydroxidhydroxid ist gleichmäßig im Silikonkautschuk verteilt und die Aggregatpartikel sind klein. Die Magnesiumhydroxidpartikel und der Silikonkautschuk sind eng miteinander verbunden, um die Kompatibilität mit der Silikonkautschukschnittstelle zu verbessern.

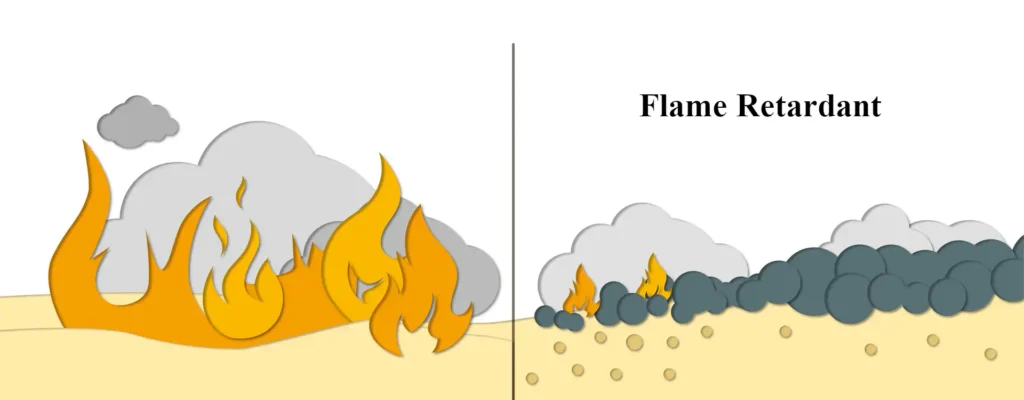

Magnesiumhydroxid absorbiert während der Zersetzung eine große Menge Wärme im Verbrennungsbereich und senkt die Temperatur des brennenden Materials. Gleichzeitig kann der zersetzte Wasserdampf das brennbare Gas verdünnen und der Wasserdampf kann auch den Kontakt zwischen Silikonkautschuk und Sauerstoff isolieren und dann eine flammhemmende Wirkung haben.

Magnesiumhydroxid hat eine gute flammhemmende Wirkung auf Silikonkautschuk. Die flammhemmende Wirkung der Silikonbehandlung von Magnesiumhydroxid ist besser als die der Behandlung von Magnesiumhydroxid mit harter Fettsäure und ungebundenem Magnesiumhydroxid. Die Beschädigung der Elektroisolationsleistung und der mechanischen Leistung des Silikonkautschuks ist bei Silikonkautschuk geringer als bei den beiden anderen. Magnesiumhydroxid ist ein Silikonkautschuk für Flammschutzmittel.