Hebei Messi Biology Co., Ltd. prepared and modified flaky magnesium oxide powder and used it as an inorganic filler. Through experiments and simulation studies, the purpose is to improve the room temperature and high temperature energy storage density of PVDF-based and PEI-based composite materials. , the paper makes a preliminary analysis of the reasons for the performance improvement, and the main research contents are as follows.

The flaky magnesium oxide powder was prepared by hydrothermal synthesis method combined with calcination treatment. Taking the breakdown field strength of the composite material as the target, the optimal hydrothermal time and ammonia concentration of the flaky magnesium oxide powder were obtained by optimizing the single factor test method. , 24h and 20wt.%, respectively, the prepared MgO powder was flake-like, with a lateral dimension of about 400nm and a thickness of about 40nm. When the powder addition amount was 2.8wt.%, the room temperature energy storage density of the prepared flaky magnesium oxide/PVDF composite material reached 16.9J/cm3, exceeding 80% of the PVDF matrix, indicating that the flaky magnesium oxide was helpful to increase the energy storage density of the material.

Taking PEI as the matrix, the effect of adding flaky magnesium oxide powder on the energy storage density of PEI-based composites with temperature was studied. When it is 3.4wt.% magnesia, the energy storage density of magnesia/PEI composite material is better at 25 ℃ and 150 ℃, which are 5.54J/cm3 and 3.79J/cm3, respectively, because of the compatibility between magnesia and PEI matrix Poor, resulting in a significant decrease in the breakdown field strength with increasing temperature.

For this reason, the silane coupling agent KH550 was used to modify the surface of the flaky magnesium oxide powder, and the optimal content of the modifier was determined by the single factor test method as m(KH550):m(magnesia)=3: 100, when adding 3.0wt.% modified flaky m-magnesia, the energy storage density of m-magnesia/PEI composites can reach 6.10J/cm3 and 5.18J/cm3 at 25℃ and 150℃ cm3, respectively increased by 10% and 8% compared with before modification, indicating that KH550 is an effective modifier for improving the energy storage density and temperature stability of MgO/PEI composites. The reason is that KH550’s -NH2 and -OC2H5 Hydrogen bonds are formed with the hydroxyl groups on the surface of magnesium oxide and PEI molecules, which enhances the compatibility of organic-inorganic two-phase materials.

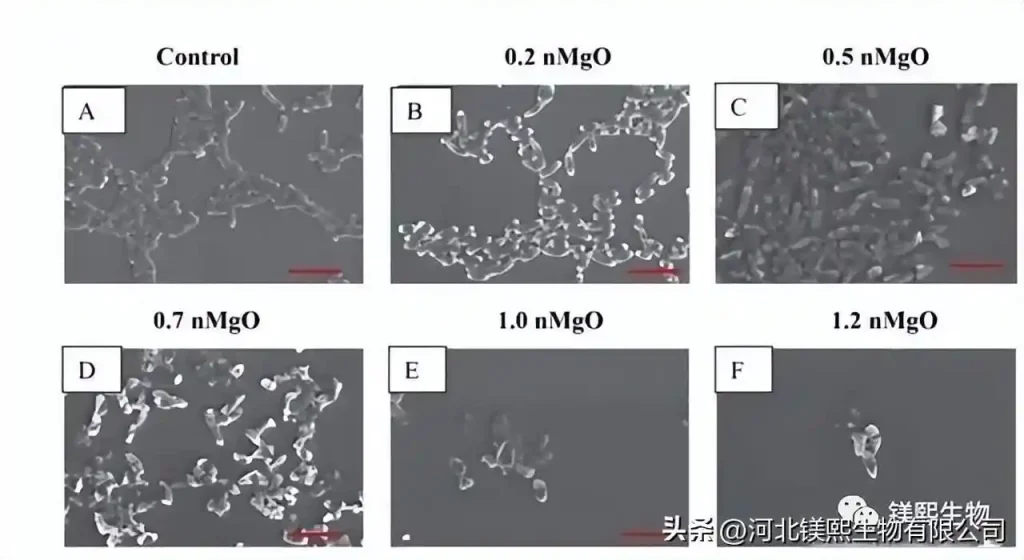

Using the finite element simulation method, with the help of COMSOL multiphysics software, the visual simulation of the internal electric field distribution of the flake magnesium oxide/PVDF composite material was carried out. The influence law of the electric field distribution inside the material.

The results show that with the increase of the addition amount of flake magnesium oxide powder, the breakdown field strength of the flake magnesium oxide/PVDF composite presents a trend of first increasing and then decreasing, and there is a better powder addition amount; the flake magnesium oxide powder The larger the lateral size of the body and the thinner the thickness, the stronger the high-pressure resistance of the composite material; when the flaky magnesium oxide filler is distributed parallel to the direction of the electric field, the high-voltage resistance of the composite material is weaker; the flaky magnesia filler in the PVDF matrix The more uniform the dispersion, the better the high pressure resistance of the composite. The simulation conclusions confirmed the experimental results of flake MgO/PVDF composites.