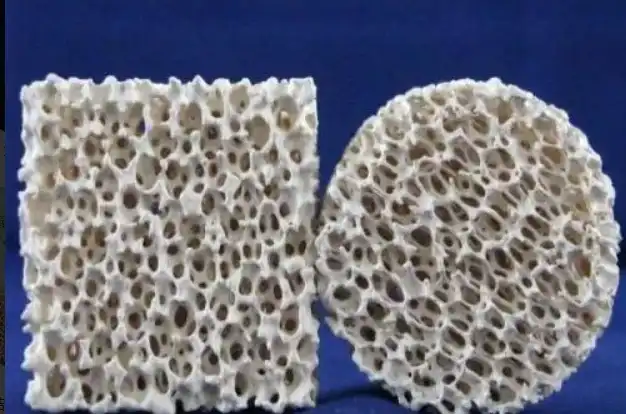

Schaumkeramiken weisen eine gute dreidimensionale Maschenskelettstruktur auf. Bei ihrer Herstellung müssen Magnesiumoxid-Zusätze verwendet werden.

Magnesiumoxid weist eine gute Adsorptions- und Filterwirkung auf Verunreinigungen in Schaumkeramiken auf, wodurch es verschiedene Einschlüsse und Verunreinigungen in Magnesium- und Magnesiumlegierungsschmelzen filtern, die intrinsische Qualität von Gussteilen verbessern und Defekte reduzieren kann und die Vorteile einer geringen Wärmekapazität, eines geringen Widerstands, einer großen Filterkapazität usw. bietet, wodurch es sich sehr gut für die Filterung von Magnesiumschmelzen und Magnesiumlegierungsschmelzen eignet.

Magnesiumoxid-Schaumkeramikfilter können in gebundene und gesinterte unterteilt werden: Die erstgenannte gebundene Schaumkeramik kann nicht zur Magnesium-Flüssigkeitsfiltration verwendet werden; die letztere wird zur Hochtemperaturisolierung verwendet, sodass hochreines mikrofeines Magnesiumoxidpulver gesintert und miteinander verschmolzen wird. Das erfordert, dass dieses Produkt eine gleichmäßige Magnesiumoxid-Partikelgröße, eine niedrige Hydratationsrate und eine gewisse Sinteraktivität aufweist.

Messi Biology erforscht und entwickelt Magnesiumoxid zur Herstellung von Schaumkeramiken. Es hat einen hohen Gehalt, eine kleine Partikelgröße und ist chargenstabil. Bei der Verwendung des Verfahrens können Produktverunreinigungen wirksam herausgefiltert werden.