Since the amount of thermally conductive powder added in the high thermally conductive interface material is relatively large, the effect of high thermal conductivity depends on the selection of thermally conductive powder. High-purity magnesium oxide is a very good filler! Studies have shown that the addition of high-purity magnesium oxide can significantly improve the performance of thermal interface materials.

As we all know, thermal conductivity refers to the ability of a substance to transfer heat energy. In solids, heat transfer is mainly via phonons. Therefore, the thermal conductivity of solid materials is closely related to the lattice structure and phonon properties. While the lattice structure of magnesium oxide is rock salt type, each magnesium ion is surrounded by 8 cations, and each oxygen ion is surrounded by 4 magnesium ions. This structure determines that magnesium oxide has good thermal conductivity. At room temperature, the purity of magnesium oxide is as high as 99% and has extremely high thermal conductivity, which can quickly transfer heat. Therefore, it is widely used in high-temperature furnaces, thermoelectric generators, heat pipes and other equipment. In addition, it is also used as insulating materials for electronic components and High temperature ceramic materials.

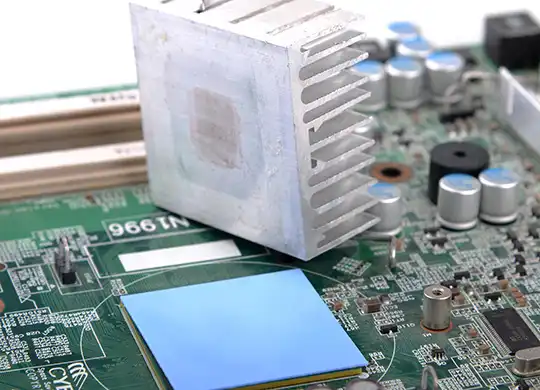

In addition to high thermal conductivity, it must also have good flame retardancy in the thermally conductive potting compound. And it has good fluidity after being fully mixed with silicone oil. At the same time, the specific gravity of magnesium oxide is moderate, which can prevent the sedimentation and compaction of the slurry due to long-term storage.

In the production of high thermal conductivity materials, the selection of magnesium oxide powder is crucial, but the influence of powder particle size on thermal conductivity cannot be ignored. Depending on the amount of addition required for different thermally conductive materials, the particle size also needs to be selected differently. Generally speaking, there are certain requirements for the large particle size added to the heat conduction powder. For example, when added to the heat conduction gasket and heat conduction potting compound filler, the large particle size is more likely to contact each other, thereby forming a heat conduction path and increasing the thermal conductivity. But the finished product is not so delicate. The smaller particle size powder has a larger surface area in contact with the substrate, and the heat transfer resistance is also greater, and the thermal conductivity is slightly lower.

Therefore, it is necessary to comprehensively consider the advantages of different particle sizes under different filling amounts, and through reasonable particle size matching, the powder can form more heat conduction networks in polymer materials and obtain materials with different heat conduction. The high-purity magnesium oxide independently developed and produced by Messi Biology can provide parameter customization services to meet the needs of the above thermal conductive materials, and is a more efficient and more secure choice.