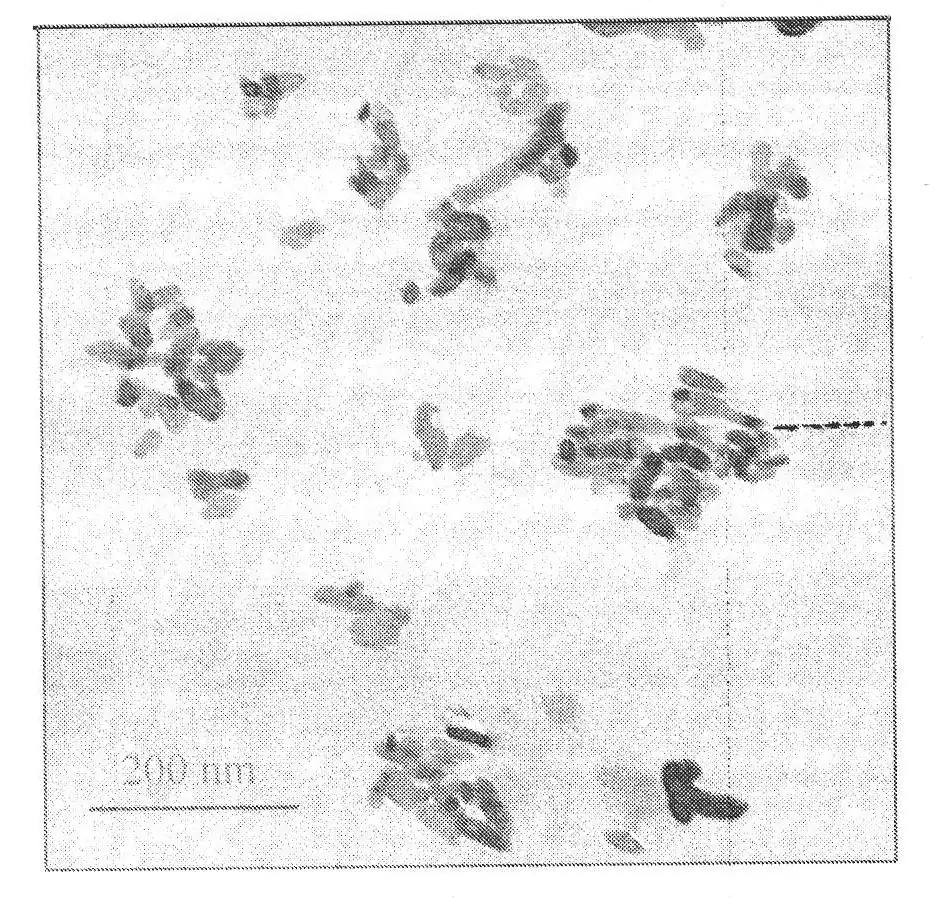

Preparation of spherical magnesium oxide by precipitation and sol-gel method

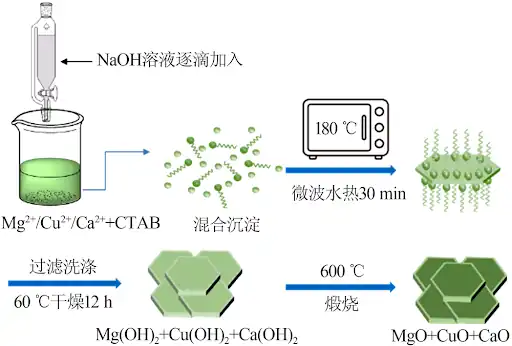

Precipitation Principle: The precipitation method utilizes the reaction of an aqueous magnesium salt solution with an alkaline solution to produce a magnesium hydroxide precipitate, which is then calcined to magnesium oxide. Steps: Dissolve a magnesium salt (such as magnesium chloride) in water to form a magnesium salt solution. Add the alkaline solution (e.g. sodium hydroxide) […]

Preparation of spherical magnesium oxide by precipitation and sol-gel method Read More »