Nano-magnesium oxide is a fairly common basic oxide. Since the melting point of magnesium oxide is as high as 2800 ° C, it has some special and excellent properties, so it can be included in the field of electronic ceramics. In terms of application, it can be divided into direct sintering into ceramics and use as a sintering aid for other ceramics.

1. Direct sintering into ceramics

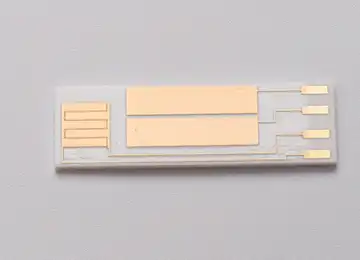

Nano-magnesia is an excellent ceramic raw material. Because of its good heat resistance and strong corrosion resistance to alkaline metal solutions, magnesia ceramics are often suitable for high-temperature environments. It can be used as a crucible for smelting metals. It is also suitable for smelting high-purity uranium and thorium in the atomic energy industry. It can also be used as a thermocouple protection sleeve. And because it has the property of allowing electromagnetic waves to pass through, it can be used as a radome and a projection window material for infrared radiation. At the same time, it is also a raw material for piezoelectric, superconducting materials, etc., and is environmentally friendly and has good lead corrosion resistance. It can also be used as a ceramic sintering carrier, especially for the sintering protection of ceramic products with corrosive and volatile substances at high temperatures such as β-Al2O3.

3. Used as a sintering aid for other ceramics

In addition, nano-magnesium oxide can also be added in the preparation process of other ceramics, which can reduce the glass transition temperature, reduce the sintering temperature, and improve the optical and mechanical properties of ceramics, thus helping us to obtain more High quality ceramic material.

For example, silicon nitride ceramics have become one of the most promising high-temperature structural materials due to their excellent high-temperature strength, thermal shock resistance, and chemical stability, but their strong covalent bonds and low diffusion coefficients make them difficult to sinter densification. However, the addition of magnesium oxide can react with silicon dioxide on the surface of silicon nitride powder to form a silicate liquid phase during the sintering process, thereby effectively promoting the sintering of silicon nitride ceramics. At present, MgO-Y2O3 composite sintering aids are generally used to realize the normal pressure sintering of silicon nitride ceramics.

In summary, nano-magnesia plays a vital role in the field of ceramics. It can be used as a basic material and an additive to improve the performance and function of ceramics, thereby promoting the progress and development of the ceramic industry.